Description

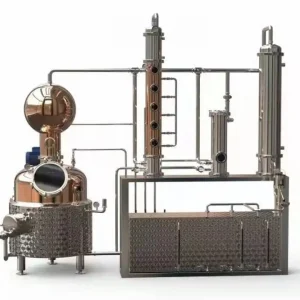

The Labonsale HC Series Heating Circulator, also known as a high temperature cycling device, is a sophisticated closed-loop instant heating system designed to meet the precise requirements of clients seeking rapid heating capabilities for high-temperature applications. Utilizing direct heat conduction methodology, this system strategically positions the heating element within the plate groove, allowing circulating cold water or oil to efficiently interface with the heating element’s surface for direct and effective heating. Its compact design facilitates rapid heating of the contained water or oil, ensuring the circulated medium achieves elevated temperatures promptly.

Importance in scientific research

In scientific research, maintaining precise temperature conditions is often critical for achieving accurate and reproducible results. Labonsale HC series high-temperature circulator allows researchers to control temperature variables precisely, enabling them to conduct experiments under controlled conditions.

It features an electric heating system with an enclosed structure engineered to prevent oil mist volatilization at high temperatures. With a large flow rate and high lift capabilities, the circulating pump efficiently delivers the heat-conducting fluid to heat the materials of supporting equipment. Widely employed in biopharmaceutical, petrochemical, medical health, and food industries requiring high-temperature environments, it serves as a versatile combination device catering to diverse industrial needs.

Compatible with a range of heating apparatuses including double-layer glass reactors, stainless steel and enamel reactors, fermentation vessels, and various circulation conduits, the high-temperature circulator facilitates precise and efficient high-temperature distillation and drying reactions.

Heating Circulator Structure

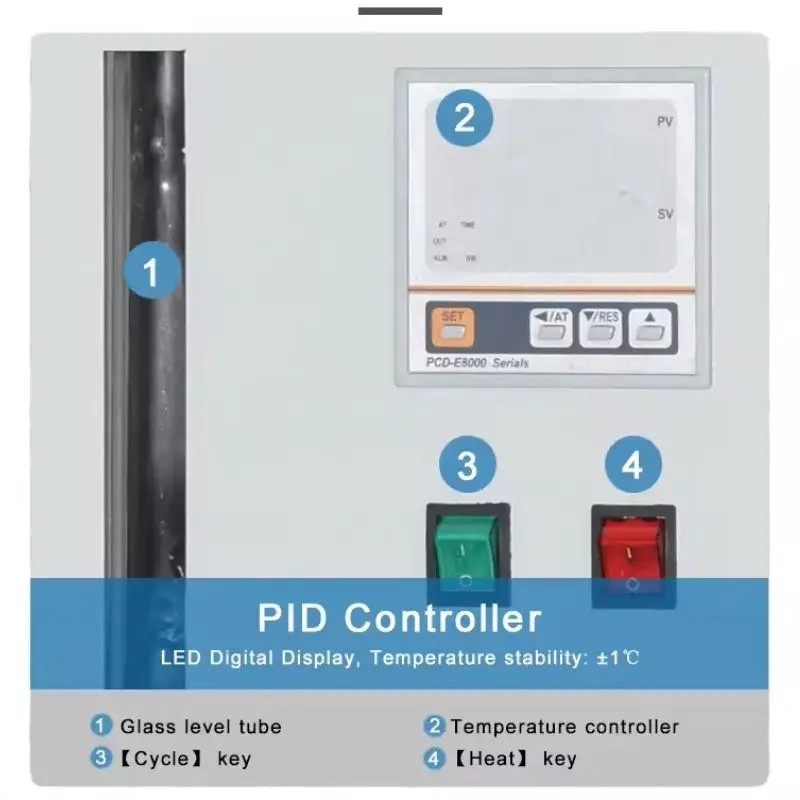

The heating circulator primarily comprises a glass liquid tube, a thermal oil inlet port, cycle and heating control buttons, and universal wheels for mobility.

Internally, the heating circulator features heating elements, circulation pumps, and precision temperature control mechanisms designed to attain and maintain precise temperatures within the circulating fluid.

HC2 Series Heating Circulator

HC2 Series Heating Circulator maximum heating temperature can reach 200℃.

Specifications of HC2 Series

| Model | HC2-0510 | HC2-2030 | HC2-50 | HC2-100 | |

| Heating Power | 1.5KW | 3KW | 5KW | 9KW | |

| Function | Provide heat source to external devices | ||||

| Cycling Ability | Type | High temperature magnetic drive pump | |||

| Power | 100W | ||||

| Flow | 20-40L/min | ||||

| Lift | 4-6m | ||||

| Temperature Control System | Thermometer Probe | PT100 | |||

| Temperature Control Type | PID intelligent temperature control, LCD large screen digital display | ||||

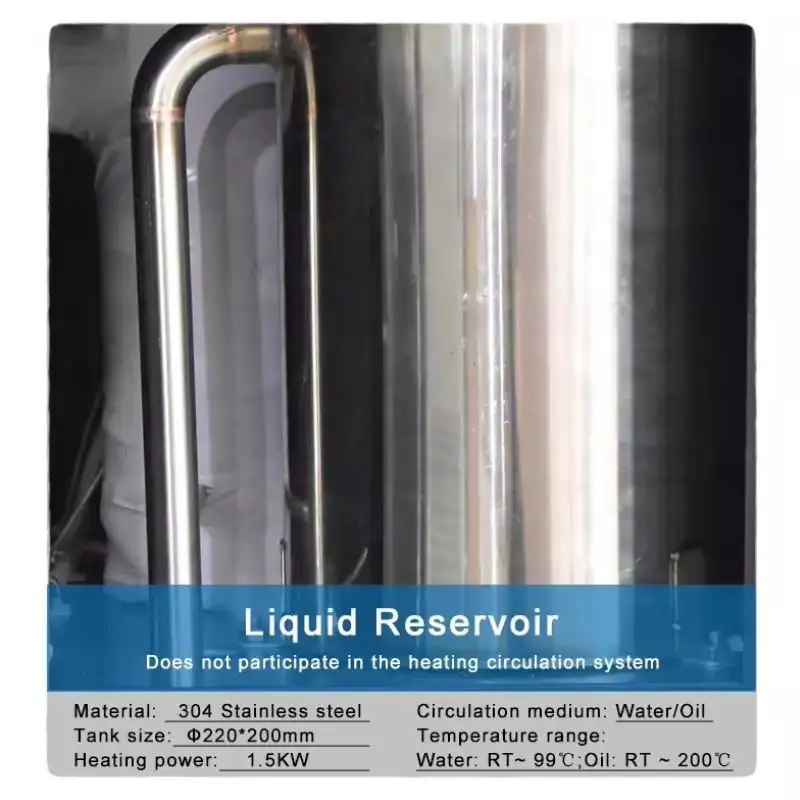

| Temperature Range | Water: RT-99℃, Oil: RT-200℃ | ||||

| Temperature Control Accuracy | ±1℃ | ||||

| Cooling System | Cooling Area | 8㎡ | 12.8㎡ | ||

| Refrigeration Capacity | 2640W | 4300W | |||

| Working Conditions | Voltage | 220V/50Hz | 380V/50Hz | ||

| Total Output Power | 1.6KW | 3.1KW | 5.1KW | 9.1KW | |

| Ambient Temperature | -10~60℃ | ||||

| Relative Humidity | <90MRH (Non-condensing) | ||||

| Environmental Pressure | 86-106kPa | ||||

| Circulating Medium | Water | Deionized or distilled water | |||

| Thermal Oil | The viscosity is not higher than 100cSt | ||||

| Size | Reservoir | Does not participate in heating cycle | |||

| Φ220*200mm | Φ220*250mm | Φ220*300mm | Φ220*400mm | ||

| Heating Tank | Φ90*200mm | Φ90*250mm | Φ90*250mm | Φ90*450mm | |

| Inlet And Outlet Valve | 4'' | 6'' | |||

| Equipment Size | 450*640*730mm | 530*650*880mm | 530*650*1080mm | ||

| Accessories | Inlet And Outlet Valve | 1 Set | |||

| Connecting Pipe | Stainless steel bellows | ||||

| Gasket | Several |

HC3 Series Heating Circulator

HC3 Series Heating Circulator maximum heating temperature can reach 300℃.

Specifications of HC3 Series

| Model | HC3-5L/10L | HC3-20L/30L | HC3-50L | HC3-100L | |

| Heating Power | 1.5KW | 3KW | 5KW | 9KW | |

| Function | Provide heat source to external devices | ||||

| Cycling Ability | Type | High temperature magnetic drive pump | |||

| Power | 0.18KW | 0.25KW | 0.5KW | 0.5KW | |

| Flow | 15L/min | 15L/min | 25L/min | 25L/min | |

| Lift | 10-15m | 12-20m | 40m | 40m | |

| Pressure | 15bar | ||||

| Temperature Control System | Thermometer Probe | PT100 | |||

| Temperature Control Type | PID intelligent temperature control, LCD large screen digital display | ||||

| Temperature Setting Range | PT100: 0~400.0℃ | ||||

| Temperature Measurement Range | PT100: -59.0~409.0℃ | ||||

| Temperature Range | Water: RT-99℃, Oil: RT-350℃ | ||||

| Temperature Control Accuracy | ±1℃ | ||||

| Working Conditions | Voltage | 220V/50Hz | 380V/50Hz | ||

| Total Output Power | 1.68KW | 3.25KW | 5.5KW | 9.5KW | |

| Ambient Temperature | -10~60℃ | ||||

| Relative Humidity | <90MRH (Non-condensing) | ||||

| Environmental Pressure | 86-106kPa | ||||

| Circulating Medium | Water | Deionized or distilled water | |||

| Thermal Oil | The viscosity is not higher than 100cSt | ||||

| Size | Reservoir | Does not participate in heating cycle | |||

| Φ200*280mm | Φ200*280mm | Φ220*280mm | Φ220*300mm | ||

| Heating Tank | Φ90*280mm | Φ90*280mm | Φ90*280mm | Φ90*510mm | |

| Inlet And Outlet Valve | DN20(6''=G3/4) | ||||

| Equipment Size | 400*540*650mm | 450*640*880mm | 450*640*1075mm | ||

| Accessories | Inlet And Outlet Valve | 1 Set | |||

| Connecting Pipe | Stainless steel bellows | ||||

| Gasket | Several |

Size reference

Ex-proof Heating Circulator(Optional)

Explosion-proof rating: EX DIIB T4GB. The glass liquid level tube ensures clear visibility of medium levels, enabling precise monitoring and control.

Details

Effortlessly regulate cycling and heating with the LED Digital Display PID Controller.

The high-efficiency heat exchange fan boasts a compact design and diminutive dimensions.

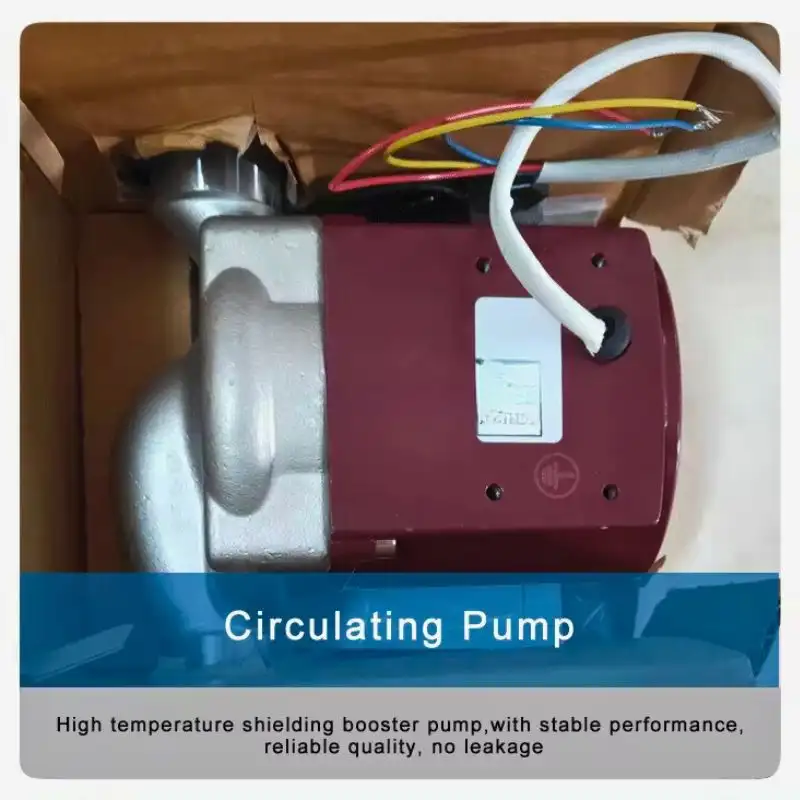

Equipped with high-grade booster pump designed for effective high-temperature shielding, characterized by steadfast performance, dependable quality, and zero leakage.

Liquid Reservoir does not participate in the heating circulation system. Sealed components ensure rapid heat transfer and minimal footprint.

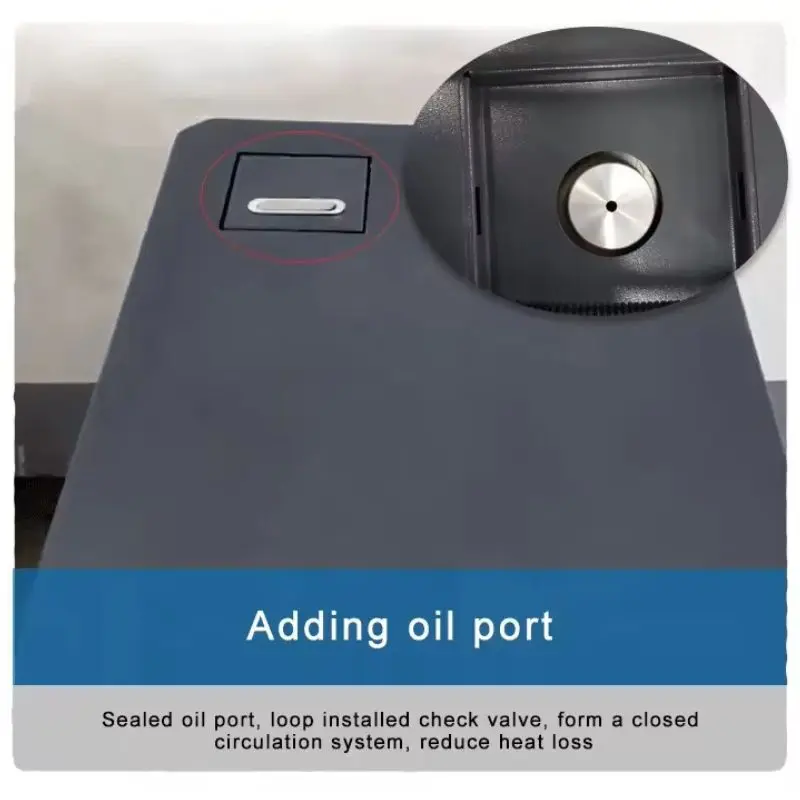

Featuring a sealed oil inlet, integrated loop-check valve, establishing a sealed circulation system to minimize thermal dissipation.

Incorporating universal wheels with foot-operated brakes for effortless mobility and user-friendly operation.

Our factory standard features stainless steel bellows engineered to withstand temperatures exceeding 100 degrees Celsius.

Components

Laboratory high temperature circulating devices consist of several key components that work together to achieve and maintain the desired temperature levels.

Heating elements

The heating elements, typically made of stainless steel or other heat-resistant materials, are responsible for heating the circulating fluid to the desired temperature. These elements are designed to provide uniform heat distribution throughout the heating bath, ensuring consistent temperature conditions.

Circulation pump

The circulation pump is responsible for circulating the fluid through the system, ensuring uniform temperature distribution. By continuously circulating the fluid, the pump helps prevent temperature gradients and hot spots, which can affect the accuracy of experiments.

Temperature control system

The temperature control system allows users to set and maintain the desired temperature with precision. This system typically includes a digital display, temperature sensors, and a feedback mechanism to adjust the heating elements as needed to achieve the target temperature.

Safety features

Many laboratory high temperature circulating devices are equipped with safety features to protect both the equipment and the user. These may include overheat protection, low-level fluid detection, and automatic shutdown mechanisms to prevent accidents and equipment damage.

Applications

High temperature cycling devices find wide-ranging applications across various scientific disciplines due to their precise temperature control capabilities.

Chemical synthesis

In chemistry laboratories, high temperature circulating devices are used for various chemical synthesis reactions that require precise temperature control. These devices enable researchers to maintain specific reaction conditions, such as refluxing, distillation, and polymerization, to achieve desired reaction outcomes.

Material testing

In materials science, laboratory high temperature circulating devices are used to study the thermal properties of materials, such as melting point, phase transitions, and thermal conductivity. By controlling the temperature with high precision, researchers can accurately measure and analyze the behavior of materials under different temperature conditions.

Pharmaceutical research

In pharmaceutical laboratories, high temperature circulating devices are employed for various drug formulation and stability studies. These devices allow researchers to simulate and study the effects of temperature on drug compounds, helping to optimize formulations and ensure product stability under different storage conditions.

Environmental studies

In environmental research, laboratory high temperature circulating devices are used to simulate environmental conditions for studying the effects of temperature on ecosystems, organisms, and pollutants. These devices enable researchers to control temperature variables precisely, allowing for more accurate and reliable experimental results.

Maintenance and Care Tips

Proper maintenance and care are essential for ensuring the longevity and performance of the devices.

Regular cleaning and inspection

Regular cleaning and inspection of the device’s components, including the heating bath, circulation pump, and temperature sensors, help prevent contamination and ensure proper functioning. Following the manufacturer’s recommendations for cleaning and maintenance procedures is essential.

Calibration checks

Periodic calibration checks are necessary to verify the accuracy of the temperature control system and ensure reliable temperature measurements. Calibration should be performed using traceable standards and procedures to maintain measurement accuracy.

Proper storage

When not in use, laboratory high temperature circulating devices should be stored in a clean and dry environment to prevent damage and contamination. Following the manufacturer’s recommendations for storage conditions and procedures is essential.

Common Troubleshooting Issues and Solutions

Despite regular maintenance, the devices may encounter common troubleshooting issues that require prompt attention.

Leaks

Leaks in the system can occur due to damaged seals, fittings, or tubing. To address leaks, it’s essential to identify the source of the leak and repair or replace the affected components as needed.

Temperature fluctuations

Temperature fluctuations may occur due to improper calibration, insufficient circulation, or external factors such as ambient temperature changes. To minimize temperature fluctuations, it’s essential to ensure proper calibration, adequate circulation, and stable operating conditions.

Pump malfunctions

Pump malfunctions, such as low flow rate or noisy operation, can affect the performance of the circulating device. To troubleshoot pump issues, it’s essential to check for clogs, air bubbles, or mechanical failures and repair or replace the pump as needed.

Go back to homepage

View more about Circulator pump on Wikipedia