Description

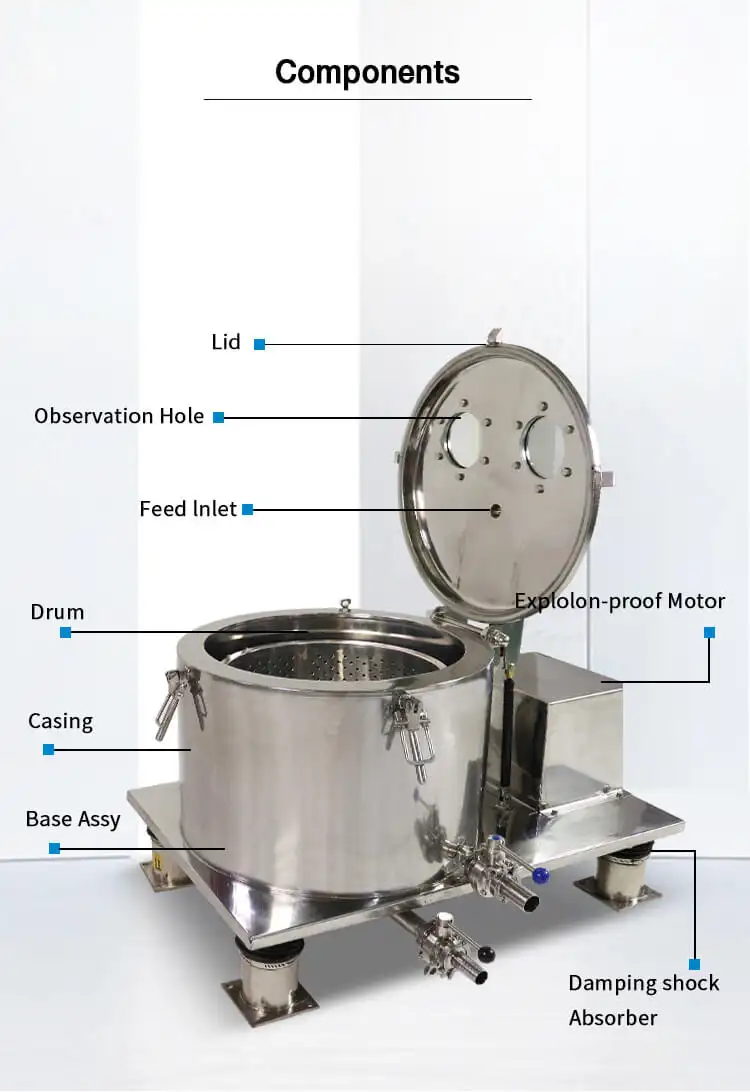

Welcome to our comprehensive Ethanol Centrifuge page, where we showcase our cutting-edge centrifugal separation technology designed to meet the demands of both laboratory and industrial applications. This high-performance machine harnesses the power of centrifugal force to separate liquid and solid components in a mixed solution, ensuring optimal extraction and unparalleled efficiency.

Ethanol Centrifuge Principle and Working Mechanism:

The Ethanol Centrifuge operates on a simple yet effective principle – it utilizes centrifugal force to rapidly separate different materials within a liquid mixture. The liquid phase is accelerated and forced out of the drum by spinning the rotating drum at high speeds, leaving behind the solid phase. This allows for the precise and efficient separation of various substances, including the extraction of desired components from plant materials.

Technical Parameter

| Model | Drum | Storage capacity (L) | Interlayer capacity (L) | Motor Power (KW) | Power voltage | ||||

| Hemp powder (LB/batch) | Capacity (L) | Diameter (mm) | Height (mm) | Rotary speed (rpm) | |||||

| PP-15 | 6.5 | 15 | 300 | 250 | 2000 | 30 | 9 | 1.1 | 220V/60Hz Single phase / three phase |

| PP-25 | 11 | 25 | 300 | 350 | 2000 | 40 | 12 | 1.5 | |

| PP-45 | 20 | 45 | 450 | 300 | 1500 | 85 | 20 | 2.2 | |

| PP-60 | 28 | 60 | 450 | 400 | 1500 | 106 | 25 | 3 | |

| PP-110 | 50 | 110 | 600 | 400 | 1250 | 175 | 33 | 4 | 220V/60Hz Three phase |

| PP-140 | 65 | 140 | 600 | 500 | 1250 | 210 | 40 | 5.5 | |

| PP-250 | 117 | 250 | 800 | 500 | 1100 | 380 | 55 | 11 | |

| PP-480 | 225 | 480 | 1000 | 600 | 1000 | 748 | 90 | 15 | |

| PP-860 | 413 | 860 | 1250 | 700 | 950 | 1250 | 130 | 18.5 |

- Superior Extraction Efficiency: Our Ethanol Centrifuge excels at extracting active ingredients from plant materials, delivering high yields and maximizing the potential of your extraction processes.

- Versatility for Different Applications: Whether you’re operating a laboratory or an industrial facility, our centrifuge is designed to meet your specific needs, ensuring reliable performance and exceptional results across a wide range of applications.

- Precise Control and Customization: With advanced programmable settings, you have complete control over rotation speed, direction, and duration, allowing you to tailor the extraction process to suit your requirements.

- User-Friendly Interface: The Ethanol Centrifuge features an intuitive interface that enables easy operation and seamless integration into your workflow, minimizing downtime and maximizing productivity.

- Robust Construction and Safety Measures: Built to withstand rigorous demands, our centrifuge is constructed with high-quality materials and incorporates safety features to ensure operator protection and long-term durability.

Applications

The ethanol soaking centrifuge separator mainly used for biomass + ethanol under low temperature to get the crude oil (a mixture of oil and ethanol). Also can be used for drying material, and other process that need soaking or drying.

a) Laboratory Ethanol Centrifuge: Ideal for research laboratories, our Ethanol Centrifuge enables scientists to extract and separate valuable compounds from various samples. From pharmaceutical research to botanical studies, this centrifuge empowers researchers with efficient and reliable extraction capabilities.

b) Industrial Ethanol Centrifuge: In industrial settings, our Ethanol Centrifuge proves invaluable for large-scale extraction and separation processes. From ethanol production to biofuel manufacturing, this centrifuge streamlines operations, improves productivity, and enhances the overall efficiency of industrial workflows.

Operating Instructions

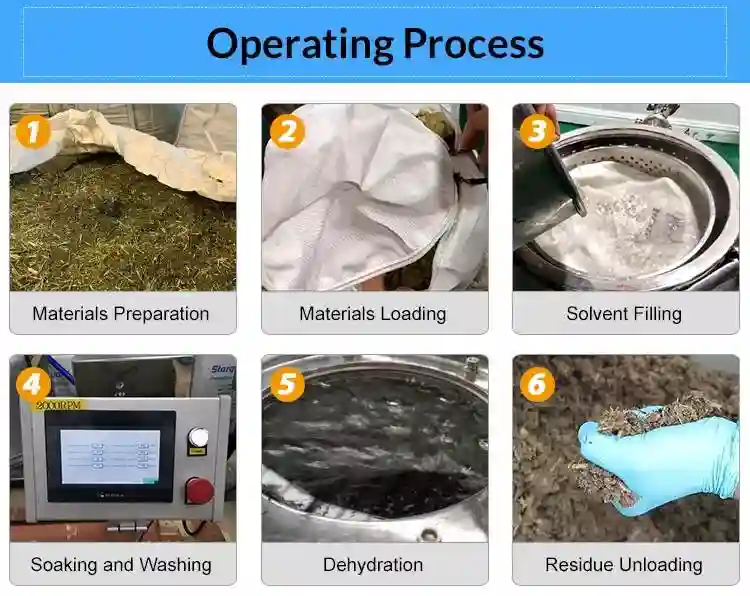

To harness the full potential of our Ethanol Centrifuge, follow these steps:

- Prepare the Filter Bag: Fill the filter bag with crushed plant material, ensuring a thorough and even distribution.

- Load the Machine: Place the filled filter bag into the centrifuge, ensuring proper positioning.

- Submerge in Alcohol: Add ethanol or alcohol to the centrifuge until the plant material is completely submerged.

- Set Low-Temperature Soak: Activate the low-temperature program to allow the active ingredients to extract slowly under controlled conditions.

- Initiate Low-Speed Rotation: Set the centrifuge to rotate at a low speed in both directions, ensuring a thorough and efficient extraction process.

- Accelerate Extraction: Increase the rotation speed to high and open the bottom discharge valve to allow the extract to be discharged.

When it comes to efficient separation and extraction, our Ethanol Centrifuge is the ideal solution for both laboratory and industrial needs. Its innovative design, advanced features, and user-friendly interface make it a reliable and indispensable tool for achieving superior results. Experience the power of centrifugal force with our Ethanol Centrifuge and revolutionize your separation processes today. Contact us for more information or to explore how our centrifuge can elevate your operations to new heights.

Go back to homepage

View more about Centrifuge on Wikipedia