Description

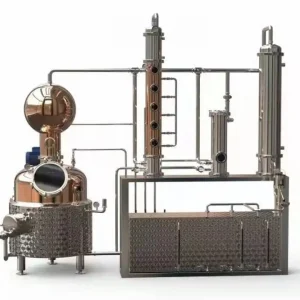

Welcome to our comprehensive choosing guide on closed loop extractors, including the highly sought-after closed loop BHO extractor, closed loop extractors, closed loop extractor kits, and closed loop butane extractors. Our cutting-edge closed loop extractor products are designed to extract solvents efficiently from solid matter, making them widely used in various industries. From extracting plant essence through ethanol washing to producing cannabis concentrates, our closed loop extraction systems offer unparalleled performance and quality.

All closed loop extractor parts can be customized, you can also upgrade the closed-loop extractor, please contact us for a quote.

At its core, a closed loop extractor is a specialized device that excels at separating solvents from solid matter. It plays a crucial role in many industrial processes, particularly in the extraction of essence from plants through ethanol washing. By employing a closed loop extraction system, the plant extract is efficiently obtained from the foliage of the plant, ensuring maximum yield and preserving the integrity of the extracted compounds.

Technical Parameter

| Model | BH-05 | BH-10 | BH-20 | BH-40 | BH-80 |

| Solvent Tank Full Volume/Recommended Volume | 36L / 25L | 60L / 50L | 128L / 100L | 182L / 150L | 239L / 200L |

| Material Column Recommended Capacity | 5 lb | 10 lb | 20 lb | 40 lb | 80 lb |

| CRC Volume | 5 L | 5 L | 10 L | 10 L | 10 L |

| Collection Tank Full Volume/Recommended Volume | 41L / 25L | 65L / 50L | 136L / 100L | 190L / 150L | 247L / 200L |

| Condenser Size(∅*H) | 8" X 12" | ||||

| Operating Temperature | -40 ~ 40℃ | ||||

| Operating Pressure | 50 ~ 150PSI | ||||

| Dimension(mm) | 1120x910x1400 | 3000x910x1550 | 3100x910x1550 | 3150x910x2000 | 4000x910x2000 |

Product Component

Closed Loop Extraction Process

The closed loop extraction process involves placing the foliage in a solvent, typically ethanol, within the closed loop extractor. The plant material is thoroughly washed with ethanol, allowing the soluble essence to dissolve into the solvent. Throughout the washing process, the closed loop extractor ensures a controlled and contained environment, preventing any leakage of solvents or unwanted substances. The dissolved essence is then collected in a separate tank, ready for further processing and utilization.

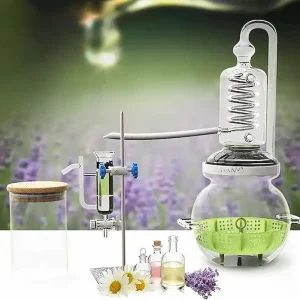

Applications of Closed Loop Extractors Plant Essence Extraction

The use of closed loop extractors is widespread in the extraction of plant essences for various industries, including perfumery, food and beverage, and herbal medicine. By utilizing ethanol washing and closed loop extraction systems, valuable essential oils, flavors, and aromatic compounds can be efficiently obtained from plant materials. This process not only ensures the purity and potency of the extracted essence but also minimizes waste and maximizes productivity.

Cannabis Concentrate Production

In recent years, closed loop extractors have gained significant popularity in the cannabis industry for their ability to produce high-quality cannabis concentrates. Closed loop BHO extractors, specifically designed for butane hash oil extraction, are widely used to extract cannabinoids and terpenes from cannabis plant material. The closed loop extraction method enables precise control over the extraction parameters, resulting in potent, flavorful concentrates that cater to the diverse demands of the market.

Advantages of Our Closed Loop Extractors Safety and Efficiency

Our closed loop extractors prioritize safety throughout the extraction process. With their robust construction and advanced safety features, such as pressure gauges and high-quality valves, they ensure a secure working environment. Additionally, our extractors are designed for optimal efficiency, minimizing solvent loss and maximizing the extraction yield, thereby enhancing productivity and cost-effectiveness.

Versatility and Customization: We understand that different industries and applications have unique extraction requirements. That’s why our closed loop extractors offer versatility and customization options. From various sizes to different materials and additional features, we provide tailored solutions that align with your specific needs. Whether you require a compact closed loop extractor for small-scale operations or a large-scale industrial system, we have the right solution for you.

Closed Loop Extractor Kit Comprehensive Kit Components

Our closed loop extractor kits are meticulously designed to provide a complete and ready-to-use extraction solution. Each kit includes essential components such as extractor vessels, collection tanks, valves, fittings, and pressure gauges. With our comprehensive kit, you can set up your closed loop extraction system seamlessly and embark on your extraction journey without delay.

Superior Quality and Durability: We take pride in offering high-quality closed loop extractor kits that are built to withstand the rigors of industrial applications. Crafted from premium materials and engineered with precision, our extractors and kit components ensure long-lasting durability and reliable performance. You can trust our products to deliver consistent and efficient extraction results, time after time.

When it comes to efficient and reliable solvent extraction, our closed loop extractors are the epitome of excellence. Whether you’re extracting plant essences or producing cannabis concentrates, our state-of-the-art closed loop BHO extractors and kits provide unparalleled performance, safety, and customization options. Invest in our closed loop extractor products and experience the power of efficient extraction in your industry. Contact us today to explore our wide range of closed loop extractors and discover the perfect solution for your needs.

Go back to homepage

View more about Extraction on Wikipedia