Description

What is Vertical Circulating Water Vacuum Pump?

The SHZ-95A(B) Vertical Type Water Circulating Vacuum Pump, also known as a recirculating water vacuum pump, water jet vacuum pump, or water ring vacuum pump, uses circulating water as the working fluid to create negative pressure through fluid jet technology. The pump can achieve a vacuum of 0.098MPa and features a compact, lightweight, and aesthetically pleasing design. Additionally, it can provide circulating cooling water to reaction devices and is an effective, oil-free, and easy-to-use solution for generating vacuum conditions.

This versatile pump is widely used in laboratories and industrial settings for evaporation, distillation, crystallization, drying, sublimation, and vacuum filtration processes. It is particularly suitable for small-scale tests in universities, research institutes, and industries like chemical, pharmaceutical, biochemistry, food, pesticide, agricultural, and biological engineering.

Technical Parameters Of Vertical Circulating Water Vacuum Pump

| Model | SHZ-95A | SHZ-95B | |

| Power | 370W | ||

| Pump Flow | 90L/min | ||

| Pump Lift | 12M | ||

| Body Material | Anti-corrosion | ||

| Voltage | 220V/60HZ | ||

| Function 1 | Sucking rate | 10 L/min *5 | |

| Max. vacuum | 0.098Mpa (735mmHg, 0.98bar, 735Torr) | ||

| Tank capacity | 50L | ||

| Vacuum port | 5Pcs | ||

| Function 2 | As circulating pump | Circulating water temperature: 0~25℃ | |

| Safety Protection | The product includes check valve to prevent cross-flow | ||

| Shell Material | Stainless steel 304 | PVG with surface electrostatic spray | |

| Dimensions | 450×340×870mm | ||

| Net weight | 37kg |

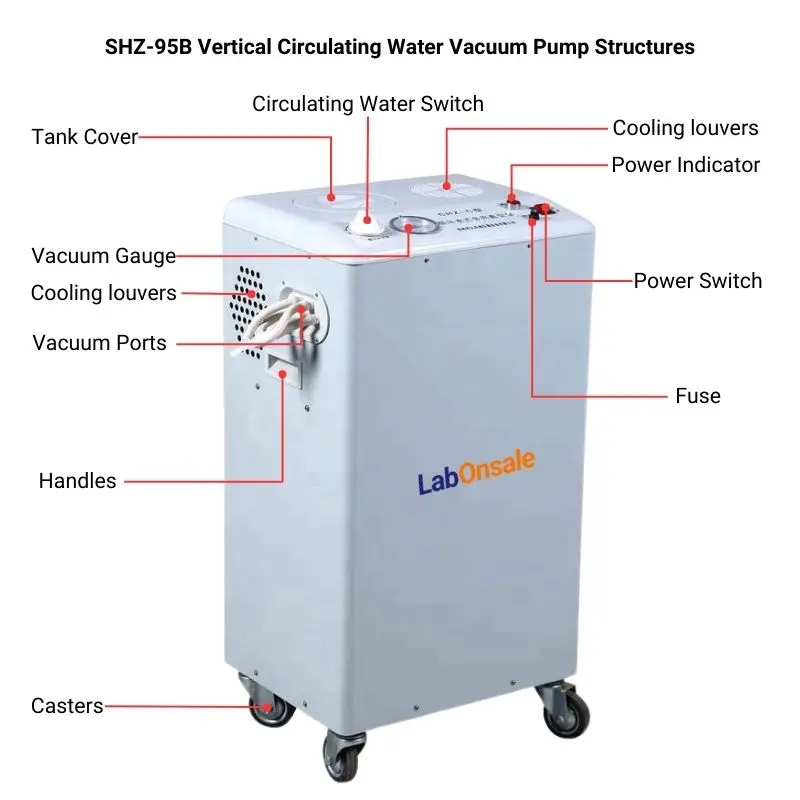

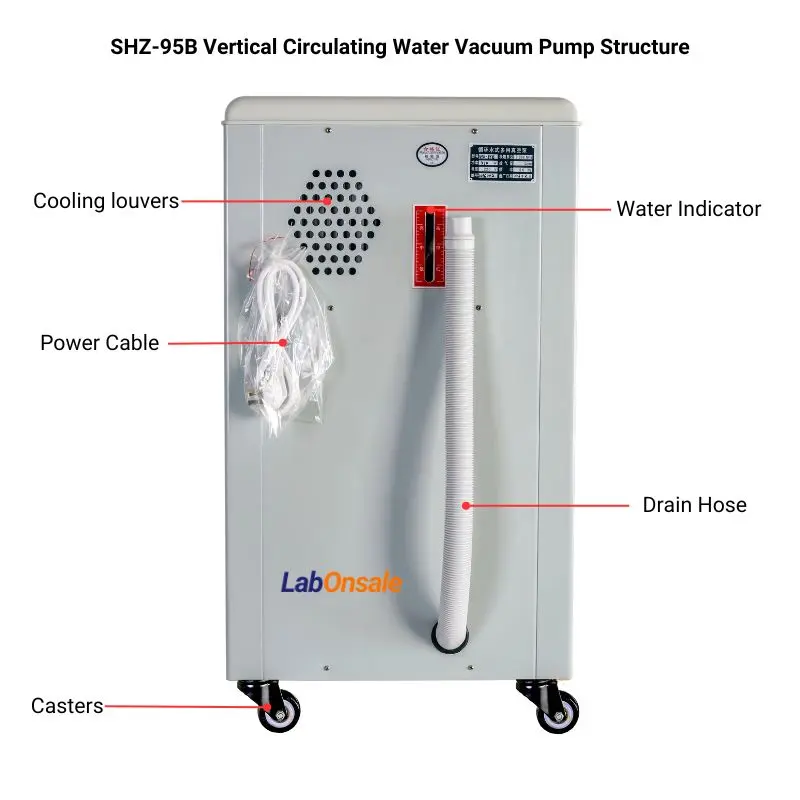

Structures

Details

Recommended Turnkey Solutions

Applications

- Chemical Industry:In the chemical industry, circulating water vacuum pumps are used for distillation, evaporation, crystallization, decompression sublimation, vacuum degassing and vacuum filtration processes. Their ability to handle corrosive substances makes them ideal for such applications.

- Pharmaceutical Industry: Pharmaceutical companies rely on circulating water vacuum pumps for processes such as solvent recovery, freeze-drying, and vacuum packaging, ensuring that products are contaminant-free and stable.

- Food and Beverage Industry: From vacuum cooling to packaging, these pumps help maintain product quality and extend shelf life in the food and beverage sector.

- Power Plants: In power plants, circulating water vacuum pumps assist in condenser evacuation and other processes that require maintaining a vacuum.

- Environmental Engineering: For environmental applications, such as groundwater remediation and air stripping, the eco-friendly nature of Circulating water vacuum pump is particularly beneficial.

- etc.

Key Benefits

Circulating water vacuum pumps offer several significant advantages compared to other types of vacuum pumps. Here are some of the key benefits:

- Efficiency and Reliability: Achieves high vacuum levels with low energy consumption, offering reliable and cost-effective operation.

- Versatility Across Applications: Circulating water vacuum pumps are suitable for a broad range of applications across various industries, including chemical processing, pharmaceuticals, and food processing.

- Contamination-Free Operation: Utilizes water as the working fluid, eliminating the risk of oil or lubricant contamination.

- Quiet Operation: Operates with minimal noise and vibration, enhancing the working environment.

- Compact and Portable: Designed for easy installation and mobility.

- Continuous Operation: Capable of running continuously with minimal maintenance.

- Ease of Maintenance: Features accessible components for straightforward cleaning, inspection, and replacement.

Function and Usage

This pump operates using circulating water as the working fluid, generating negative pressure through jet technology. It is a newly designed vacuum air pump that not only functions as a vacuum suction device but also supplies cooling circulating water to reactors.

This pump is extensively utilized in processes such as evaporation, distillation, crystallization, decompression sublimation, and other similar operations. It is an ideal instrument for environmental protection, biochemistry, medical services, the chemical industry, and scientific research, making it suitable for major and medium-sized colleges and universities.

Features

- Water Conservation: Significantly saves water resources by allowing water to be reused multiple times, making it ideal for high-floor laboratories with limited water supply.

- Energy Efficiency: Saves over 35% electricity compared to other vacuum pumps, enhancing cost-effectiveness.

- High Vacuum Performance: Specialized fluid muffler reduces gas in water, enhancing vacuum levels and minimizing noise by reducing friction between gas and fluid.

- Versatile Operation: Equipped with double taps and double gauges for independent or parallel use, suitable for various vacuum needs, including large-scale rotary evaporators and reaction kettles.

- Corrosion Resistance: The pump is constructed with materials resistant to acids, alkalis, and solvents to ensure durability and reliability. The pump spindle is made of stainless steel, while key components such as the pump head, impeller, and jet flow are crafted from acid and alkali-resistant materials, including A.B.C project plastic, copper, and plastic rings. The water tank is entirely made of plastic, making it impervious to corrosive substances.

- Durable Construction: The tank body is made of polyvinyl chloride (PVC), and the outer shell is high-quality carbon structural steel with electrostatic spraying for enhanced durability.

- Easy Mobility: Equipped with casters for easy movement and flexible distribution in labs and workshops.

- Automatic Water Replacement: Regular water replacement ensures clean water, maintaining optimal vacuum conditions and preventing scale buildup. The cycle is shortened when pumping corrosive gases.

- Quiet and Stable Operation: Designed for low noise and stable performance, with a check valve on the exhaust pipe to prevent water backflow during accidental shutdowns.

- Multi-functional: Its primary function is as a vacuum pump with five vacuum ports that can operate either independently or in parallel. Additionally, it functions as a circulating pump, providing cooling water to a reactor. By connecting the inlet port to tap water and the outlet port to the reactor, the pump can continuously circulate water, preventing temperature rise and ensuring consistent vacuum levels.

- High-Quality Components: Features copper injectors, PP tee junctions, check valves, and gas-extraction nozzles, as well as stainless steel pump bodies and impellers.

How Does a Vertical Circulating Water Vacuum Pump Work?

Understanding the operational principles of a vertical circulating water vacuum pump is essential for grasping its efficiency and reliability. Here’s a step-by-step breakdown:

- Water Circulation: The circulating water vacuum pump starts by circulating water through the system. This water creates a seal, essential for the vacuum process.

- Vacuum Creation: As the impeller rotates, it reduces the pressure within the chamber, creating a vacuum. This vacuum is maintained by the continuous circulation of water.

- Suction and Discharge: The vacuum draws air or gases through the suction pipe, which are then expelled through the discharge pipe, leaving behind a low-pressure environment.

Operation Manual

1) Add Enough Circulating Water.

Put the machine smoothly on the working place. When first use, open the lid and fill the tank with cooling water. Once added water can be reused, but to change the water at least once a week.

2)Connect Tube

Find the “Y” three-way pipe in the package, corresponds to two vacuum ports to install it with the match equipment.

3)Power On To Made Vacuum Operation

Before power on, need checking the circulating switch is closed, then press the power switch on the vacuum pump can working for vacuum, the vacuum degree can view the vacuum meter.

4)As Circulating Pump

Connect the vacuum device to the inlet and outlet corresponding, rotating the circulating witch to “ON”, can operate continually circulating water to reactor.

5) Improve Vacuum

When the water circulation pump needs long time operation, in order to guarantee water temperature in the water tank not rising, the vacuum degree not reduce, and not affect the experimental operation, you can connect the water hose with water source (or tap water), forming a natural outside circulation status, and it can remain the water temperature inside not rise, and the vacuum not reduce.

Maintenance Tips

- Regular Water Replacement: Replace the water in the flume regularly to maintain water quality, vacuum degree, and avoid dirt stains.

- Handling Corrosive Gases: When extracting corrosive gases, shorten the water replacement period.

Common faults and maintenance methods

| Fault | Fault Cause | Maintenance Methods |

| No vacuum | 1. Vacuum taps blocked by sundries.

2. The filter at the bottom blocked by sundries. 3. Vacuum taps coil buckling loose |

1.Eliminates the nozzle sundries.

2.Eliminates the filter sundries, keep the water clean. 3.Tighten the coil by hand. |

| Vacuum meters hands do not move or swing | 1.Ventilation keyway of sealing screws behind the meters blocked.

2.Meter hands swing, because of the backwater valve or the vacuum nozzle leaks air. |

1.Remove the vacuum meters,clean the ventilation keyway.

2.Tighten the rubber hose connection plug, check the backwater valve pad, clean the backwater valves, tighten the vacuum nozzle. |

| Do not start or leakage | 1. After power, the motor humming but not start is for the fan blade is out of work.

2. The motor suddenly stopped was because line outage or the fuse explodes. 3. The cover hemp hand, mainly because of the wire connect the shell or the plug without earth wire. |

1.Cut off the power, use water prod the blades inside the motor cover to help move a few laps and then turn it on again.

2.Check the circuit, Replace the fuse and dredge the circuit. 3.Exclude shell connect, add the earth wire. |

| Matters need attention | Because the pump with mechanical seal, start only after adding water, but empty running is strictly prohibited, in case the mechanical seal part damaged. | |

Go back to homepage

View more about Vacuum pump on Wikipedia