Description

Supercritical CO2 extraction is a process that separates one component, known as the extractant, from another component, termed the matrix, utilizing supercritical fluids, with carbon dioxide (CO2) being the predominant solvent. Labonsale supercritical CO2 extractors are renowned for producing safer, cleaner, and purer oils from botanical plant materials, finding widespread application in industries such as food, cosmetics, and pharmaceuticals.

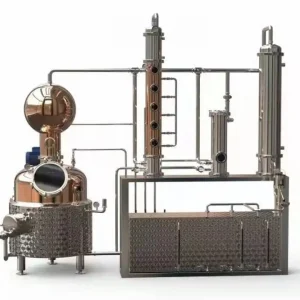

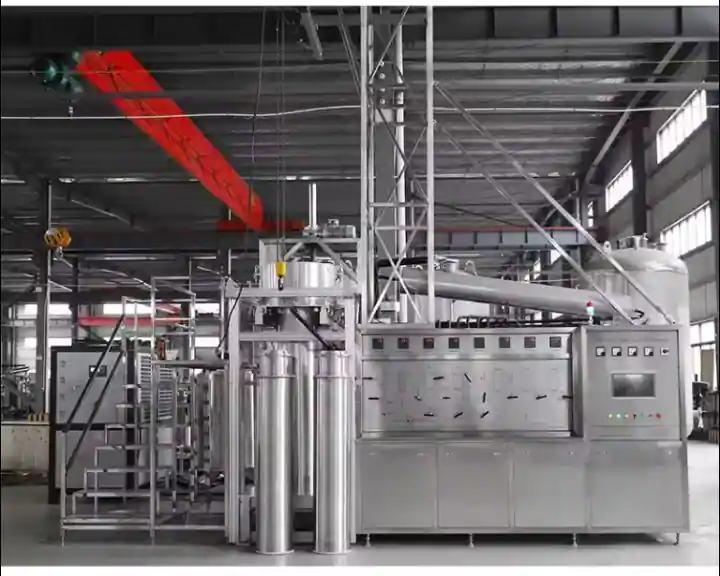

Labonsale is a leading supplier of supercritical CO2 extraction solutions in China, offering a range of standard and customized models tailored to your requirements. Our equipment spans various volumes and pressure ratings, with throughput capabilities ranging from 5 lbs of dry biomass per day to 15,000 lbs per day. With a typical lead time of just one month, we ensure prompt delivery to meet your project timelines.

In addition to our equipment offerings, we specialize in providing turnkey botanical extraction solutions, particularly for hemp and cannabis extractions. With over 100 commissioned supercritical CO2 extractor systems worldwide, we bring extensive experience and expertise to every project, ensuring optimal results for our clients.

What is supercritical CO2 extraction?

Supercritical fluid extraction is a technique that separates extracts from a mixture matrix using supercritical fluids. Among these fluids, carbon dioxide (CO2) is the most widely utilized. Supercritical fluids exist in a unique state between gases and liquids, known as the supercritical state, which occurs when pressure and temperature surpass the critical point. In this state, the fluid displays characteristics of both liquids and gases, with a density akin to liquids and a viscosity closer to gases. This property makes supercritical fluids, such as CO2, highly effective as extraction agents. They can selectively dissolve target compounds based on polarity, boiling point, and molecular weight. Overall, due to their unique properties, supercritical fluids serve as ideal extraction solvents in various industries, offering advantages such as low-temperature operation, minimal residue in extracts, and efficient extraction processes.

Principle of supercritical carbon dioxide extraction

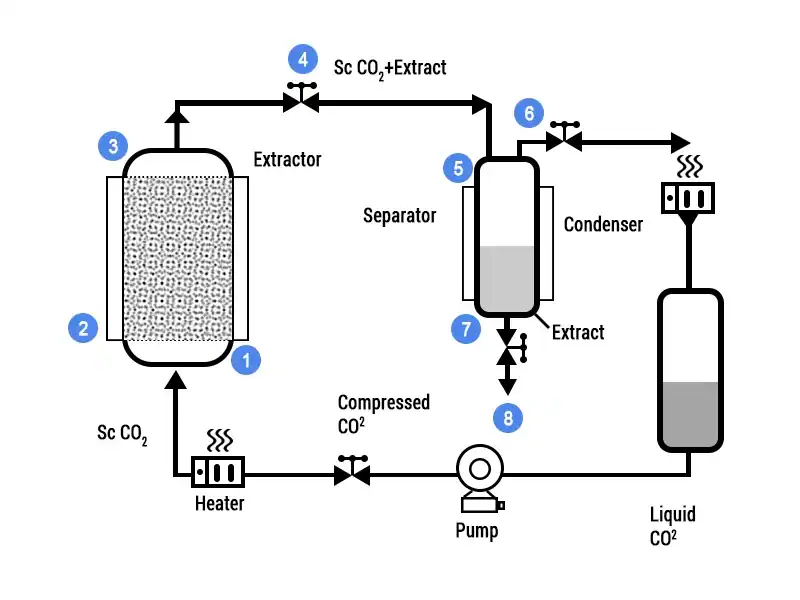

The principle behind a supercritical CO2 extraction machine and its separation process relies on the interplay between the dissolving capacity of supercritical fluid and its density, which is governed by pressure and temperature. Under the special temperature and pressure (temperature higher than 31 Celsius degrees, and pressure higher than 1071PSI), CO2 steps into a supercritical state. Carbon dioxide becomes a supercritical fluid after that with low viscosity and no interfacial tension, thus improving its capacity for solubility and therefore achieving higher efficiency of extraction. In the supercritical state, the fluid comes into contact with the substance to be separated, enabling selective extraction of components based on factors such as polarity, boiling point, and molecular weight. It’s important to note that the extract obtained at each pressure range may not be singular, but through precise control of conditions, an optimal blend of components can be achieved. Subsequently, by decompressing and raising the temperature, the supercritical fluid is converted back into a regular gas, allowing for the separation and purification of the extracted material. Thus, the highly critical CO2 fluid extraction process seamlessly combines extraction and separation procedures, resulting in efficient and effective purification.

How does Supercritical CO2 Extractor work?

- Load cannabis into the chamber.

- CO2 enters the supercritical state under optimal temperature and pressure conditions.

- The supercritical CO2 dissolves the cannabis.

- The liquid mixture containing cannabis oil is conveyed to the separator by the supercritical CO2.

- Upon reaching the separator, the supercritical CO2 reverts to a gas phase and separates from the liquid due to decreased pressure.

- The CO2 gas is directed to a storage tank for future use.

- Meanwhile, the cannabis oil and other compounds settle at the bottom of the separator.

- The collected oil and compounds are transferred to a vessel for subsequent treatment steps.

Details

Models and components

Supercritical CO2 extraction equipment comes in various models, including SFE-5L, SFE-10L, SFE-25L, and SFE-50L. These systems consist of essential components such as a refrigerator, gas storage tank, liquid carbon dioxide pump, modifier pump, raw material pump, heat exchanger, extractor, unloader, feed valve, discharge valve, pressure relief valve, pressure gauge, nitrogen cylinder, and tanks for raw material and modifier storage. Additionally, high-pressure CO2 pumps are integral components of these systems.

Benefits

- Higher Pressure Rating: Labonsale offers supercritical CO2 extractors with a pressure rating of up to 50 Mpa (7250 PSI), surpassing competitors.

- Double Safety Protection: Our extractors feature over-pressure protection gauges and safety valves, ensuring enhanced safety measures.

- Versatile: Suitable for both laboratory and industrial applications, with vessel capacities ranging from 0.5L to 3000L.

- Commissioning & Training: We provide onsite or remote commissioning and training services to ensure optimal operation.

- Cost-Effective: Our extractors offer lower power and ethanol consumption, along with a smaller footprint, resulting in cost savings.

- Safety: Utilizing non-toxic and non-flammable CO2, our extraction process is safer compared to alternative methods.

- Accessibility: Equipped with an automatic PLC controller and complete standard operating procedures (SOP), our extractors offer ease of use.

- Support: Labonsale offers short lead times of within one month, along with turnkey solution design and customization support.

Advantage

- Efficient CO2 Recovery: Labonsale’s closed-loop system can recover over 95% of CO2, ensuring minimal waste and environmental impact.

- Precise Control: Our systems allow for easy adjustment and precise control of pressure and temperature, optimizing extraction conditions.

- High-Pressure Pump: Featuring a high-efficiency CO2 high-pressure pump, our systems can quickly increase pressure for efficient extraction processes.

- User-Friendly Design: Labonsale’s CO2 extraction systems boast a user-friendly CO2 flow route design, complete with a self-explanatory flow chart for simple training and operation.

- Easy Installation: With 99% of the system pre-assembled before shipping, installation at the customer site is straightforward and hassle-free.

- Enhanced Pump Longevity: Our systems incorporate a special design within the pump piston system, extending the pump’s lifetime and requiring minimal maintenance.

- Low Extraction Temperature: Designed for low extraction temperatures, our systems are ideal for extracting and purifying heat-sensitive compounds while preserving their integrity.

Case Study

To extract peony essential oil using supercritical CO2 extraction equipment, a systematic process is followed:

- Cleaning: The roots, stems, leaves, and flowers of peonies are thoroughly washed to remove impurities and soil. After cleaning, the water is drained for later use.

- Drying: The washed peonies are then sent to a drying room equipped with drying equipment. The drying process involves maintaining a temperature between 40 to 70 degrees Celsius for 3 to 8 hours to reduce moisture content to less than 7%.

- Pulverization: Once dried, the roots, stems, leaves, and flowers are pulverized into chaff using a crop straw pulverizer, resulting in peony scraps.

- Extraction: Approximately 300kg of peony pieces are placed into the extractor, ensuring a tight seal. The liquid from the storage tank is pumped into the vaporizer through a high-pressure pump. It then enters the extractor in a critical fluid state for extraction.

- Pressure and Temperature Adjustment: The pressure and temperature within the extractor are adjusted to be between 10Mpa to 45 Mpa and 32 ℃ to 80 ℃, respectively. The mixed fluid undergoes decompression separation in the separator, with pressure controlled between 4MPa to 10Mpa and temperature ranging from 20 ℃ to 80 ℃.

- Extraction and Separation: Care is taken to prevent excessive pressure within the extractor. The fluid rich in peony essential oil is directed to the separator, where it undergoes separation from CO2. The separated pure essential oil is cooled by the liquefier and returned to the liquid storage tank, completing the extraction cycle.

- CO2 Recovery and Disposal: CO2 gas in the tail gas tank is recovered by the compressor for further extraction and stored in the liquid CO2 storage tank. Extracted peony essential oil is periodically released and measured for quality control purposes, while the remaining peony scraps are discharged from the bottom cover of the extractor.

Application

- Extraction of biologically active molecules from medicinal plants, including the extraction and separation of alkaloids.

- Extraction of lipids from different microorganisms, for lipid recovery or removal from glycosides and proteins.

- Extraction of anti-cancer substances from various plants, such as paclitaxel from Taxus chinensis bark and branches for cancer prevention and treatment.

- Extraction of vitamins, particularly vitamin E.

- Purification of various active substances, either natural or synthetic, to eliminate unwanted molecules (e.g., pesticides) and obtain purified products.

- Processing of natural antibacterial or antioxidant extracts from herbs and spices like basil, thyme, garlic, and onion, as well as botanicals like chamomile, chili powder, licorice, and fennel seeds.

Go back to homepage

View more about Supercritical fluid extraction on Wikipedia