Description

Stainless steel reactors are robust and versatile equipment used in various industries for chemical processing. Constructed with high-quality 304 or 316 stainless steel, these reactors provide exceptional performance, durability, and safety. In this comprehensive guide, we will explore the key features, benefits, types, and applications of stainless steel reactors, ensuring you have the necessary information to make an informed decision for your industrial processes.

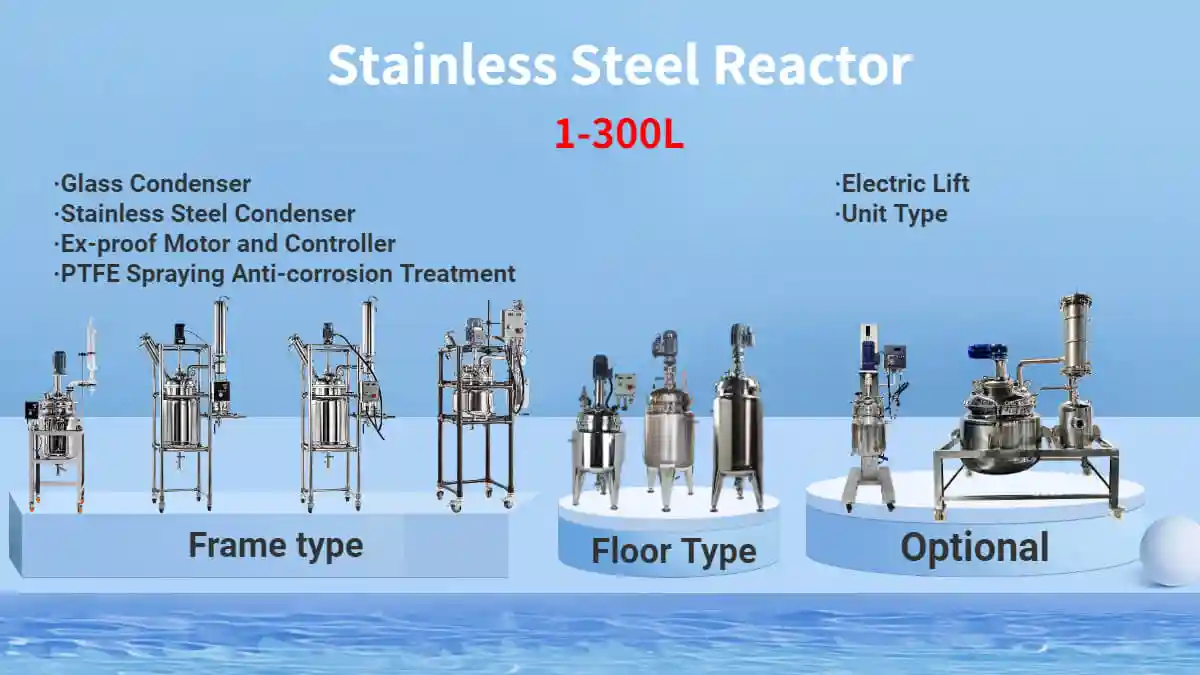

Types of Stainless Steel Reactors:

We provide three types of stainless steel reactors to cater to different needs:

- Frame-Type Reactors: These reactors are available in various configurations, including glass condensers, stainless steel condensers, explosion-proof motors and controllers, and PTFE spraying anti-corrosion treatment. Optional features such as electric lift and unit types are also available. The capacity of these reactors ranges from 1L to 300L, providing flexibility for different scales of processes.

- Floor-Type Reactors: Designed for larger-scale applications, our floor-type stainless steel reactors are characterized by sturdy construction and efficient design. These reactors can handle higher volumes and more demanding processes, offering reliability and efficiency.

- Customized Reactors: We understand the uniqueness of each process, and thus, offer customized stainless steel reactors tailored to your specific requirements. Our team of experts collaborates closely with you to design and manufacture reactors that align with your process needs, ensuring optimal performance and efficiency.

Technical Parameter

| Stainless Steel Reactor(Frame type) | |||||

| Model | SS-5L | SS-10L | SS-20L | SS-30L | SS-50L |

| Reaction Capacity | 5L | 10L | 20L | 30L | 50L |

| Jacketed Volume | 2L | 3L | 6L | 10L | 16L |

| Material | SS304 | ||||

| Thickness | Lining:4mm, shell:4mm | ||||

| Motor | 120W | 200W | |||

| Rotating speed | 0-600rpm | ||||

| Controller | Speed adjustment, temperature and speed LCD digital display | ||||

| Voltage | 110V/220V, 50/60Hz | ||||

| Working pressure | -1~0.49Mpa. | ||||

| Vacuum seal | 0.098Mpa | ||||

| Constant pressure drop funnel | Stainless steel 500ml | Stainless steel 1L | Stainless steel 2L | ||

| Machine size(mm) | 700*600*1950 | 700*600*2030 | 750*650*2150 | 750*650*2450 | 750*650*2450 |

Key Features and Benefits

Stainless steel reactors offer numerous advantages due to their excellent mechanical properties and corrosion resistance. They can withstand high working pressures and impacts from solid material feeding. With their wide temperature range, stainless steel reactors exhibit good heat resistance, allowing for efficient heat transfer and rapid temperature changes during processes.

Our stainless steel reactors consist of a tank body, tank cover, agitator, transmission device, shaft seal device, and frame. To optimize thermal performance, heating devices and three-layer vacuum insulation layers can be configured based on your specific process requirements.

Applications

Stainless steel reactors find extensive applications in various industries:

- Chemical Industry: Stainless steel reactors are crucial for chemical processes such as synthesis, polymerization, and distillation. Their corrosion resistance allows for handling aggressive chemicals, making them indispensable for producing pharmaceuticals, dyes, resins, and specialty chemicals.

- Petrochemical Industry: In the petrochemical industry, stainless steel reactors play a vital role in refining, cracking, and hydrogenation processes. They can withstand high pressures and temperatures associated with petroleum refining, making them suitable for producing fuels, lubricants, and petrochemical intermediates.

- Food and Beverage Industry: Stainless steel reactors are highly valued in the food and beverage industry for processes such as fermentation, brewing, and flavor synthesis. Their hygienic properties, resistance to food acids, and ease of cleaning ensure product purity and quality.

- Pharmaceutical Industry: Stainless steel reactors are essential in pharmaceutical manufacturing, including drug synthesis, vaccine production, and other pharmaceutical processes. The ability to maintain strict hygiene standards and control process parameters is critical in pharmaceutical production, making stainless steel reactors a preferred choice.

- Biotechnology and Biochemical Industry: Stainless steel reactors are extensively used in biotechnology and biochemical processes, such as cell culture, enzyme production, and biofuel production. Their robustness, thermal stability, and corrosion resistance provide an optimal environment for biological reactions.

- Research and Development: Stainless steel reactors play a crucial role in research and development laboratories, where scientists and engineers explore new processes, develop new materials, and optimize reaction conditions. The flexibility of stainless steel reactors allows for scalability and adaptability during the R&D phase.

Stainless steel reactors offer a reliable and efficient solution for chemical processes in various industries. With their exceptional features, including mechanical strength, corrosion resistance, and heat transfer capabilities, our stainless steel reactors provide optimal performance and durability. Whether you require a frame-type reactor, floor-type reactor, or a customized solution, our team is ready to assist you in choosing the right stainless steel reactor for your specific process requirements. Contact us today to learn more about our stainless steel reactors and how they can enhance the performance and productivity of your chemical processes.

Real Shot

Go back to homepage

View more about Batch Reactor on Wikipedia