Description

Our cutting-edge reactor leverages specific temperature and pressure conditions to dissolve materials that are typically challenging to dissolve, poorly soluble or the reaction product of the dissolving substance. By carefully controlling the solution’s temperature, we induce convection to create a supersaturated state, fostering crystal growth. Widely utilized in college laboratories, this reactor plays a pivotal role in the preparation and synthesis of nano-material compounds. Additionally, it offers an excellent platform for conducting small-scale crystal growth synthesis reactions.

The Hydrothermal Synthesis Reactor is a state-of-the-art solution designed to operate under specific temperature and pressure conditions, enabling the dissolution of materials that are difficult to dissolve, poorly soluble, or the reaction product of the dissolving substance. By controlling the solution’s temperature, this advanced reactor induces convection, forming a supersaturated state and promoting crystal growth.

With widespread use in college laboratories, the Hydrothermal Synthesis Reactor is an indispensable tool for preparing and synthesizing nanomaterial compounds. Its compact design and precise temperature control make it ideal for conducting small-scale synthesis reactions, particularly in crystal growth experiments.

Operating within a controlled temperature and pressure range, our Hydrothermal Synthesis Reactor offers numerous benefits for researchers and scientists in various fields.

Technical Parameter of Hydrothermal Synthesis Reactor

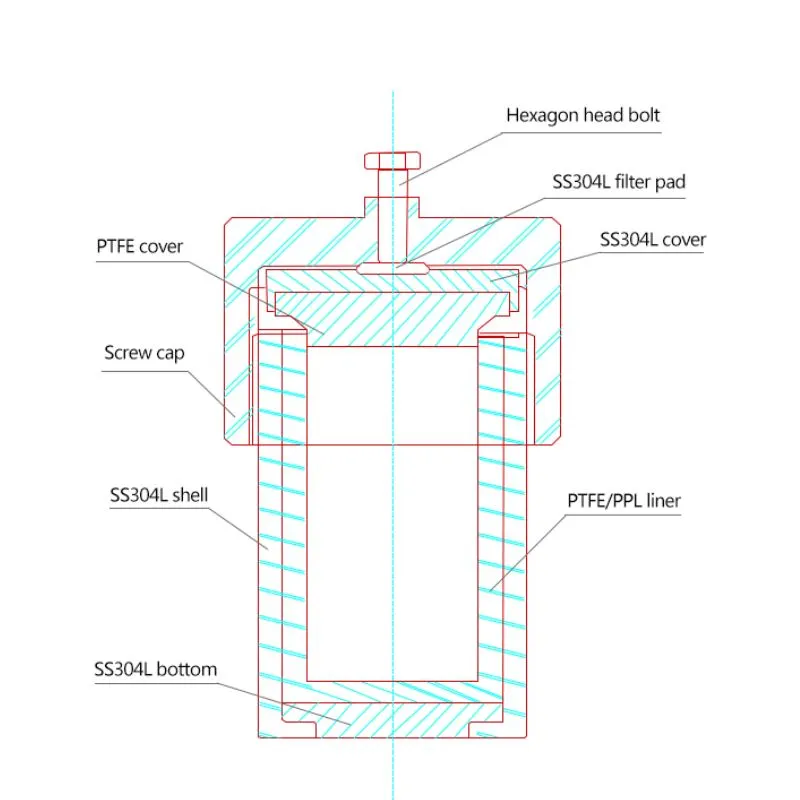

Material: 304 Stainless steel Shell and PTFE(Teflon)Lining; The PPL lining is optional

| Model | Capacity | Lining Size(mm) | Net weight(kg) | Material |

| KH-25ml | 25ml | Ø32.8×61 | 1 | 304 Stainless steel Shell and PTFE(Teflon)Lining;The PPL lining is optional |

| KH-50ml | 50ml | Ø40×78 | 1.5 | |

| KH-100ml | 100ml | Ø48.7×94 | 2.5 | |

| KH-150ml | 150ml | Ø57.5×114 | 4.5 | |

| KH-200ml | 200ml | Ø62.7×133 | 5 | |

| KH-250ml | 250ml | Ø64.9×133 | 5.5 | |

| KH-500ml | 500ml | Ø83.5xH164 | 9 | |

| KH-1000ml | 1000ml | Ø117xH150 | 16 |

Main Technical Details

1)Working pressure:≤3Mpa

2)Working Temp.:PTFE Lining Top Temperature ≤230℃, PPL Lining Top Temperature ≤280℃.

3)Solvent addition: It is usually 60% ~ 80%of the inner cup capacity

4)Heating and Cooling Rate:≤5°C/min

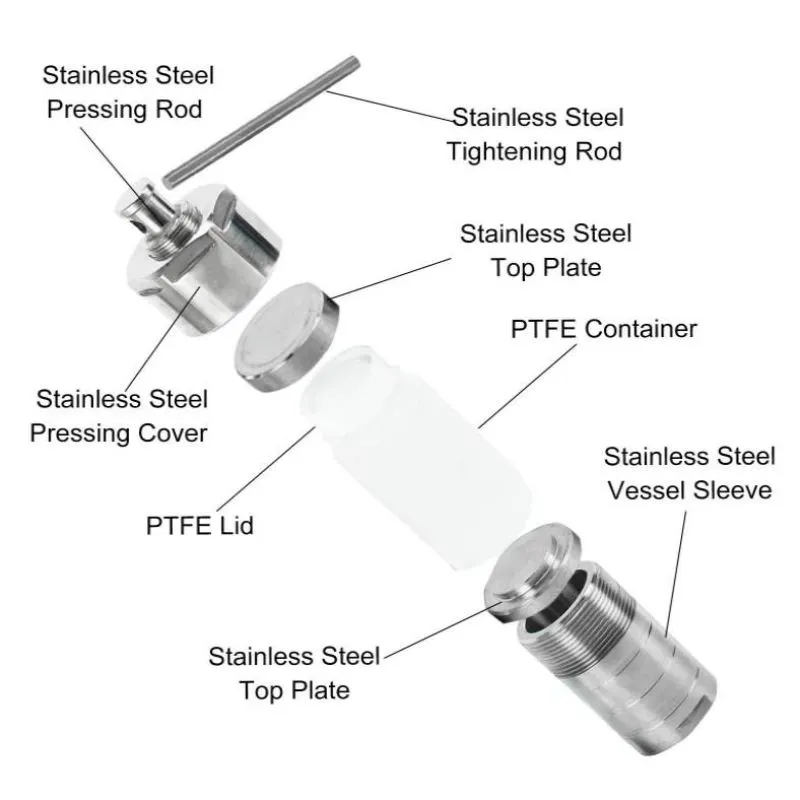

Product Component

The whole set of Hydrothermal Synthesis Reactor consists of a stainless steel pressing cover, a stainless steel tightening rod, a stainless steel vessel sleeve, 2 stainless steel top plates, a PTFE lid, and a PTFE container.

Operating Manual

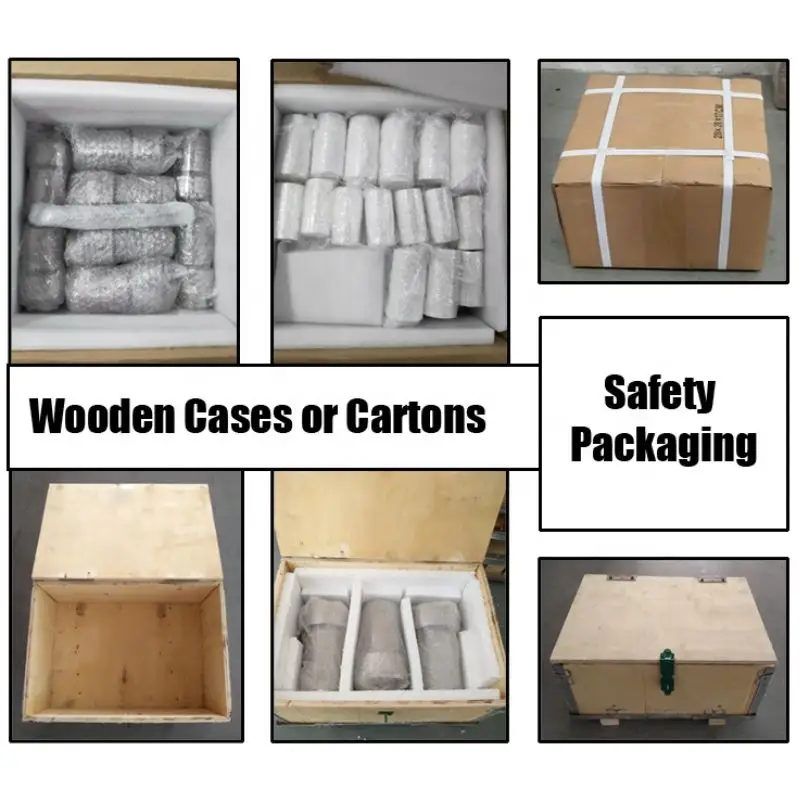

Packaging

-Wooden/Carton case with insulation inserts and protective foam;

-Both neutral and customized packaging can be available.

Key Features

Precise Temperature and Pressure Control: Equipped with advanced temperature and pressure control systems, our reactor allows researchers to achieve optimal conditions for material dissolution. This precise control ensures reproducibility and reliability in scientific research and experimentation.

Enhanced Dissolution Capability: The Hydrothermal Synthesis Reactor excels in dissolving materials that are traditionally challenging or poorly soluble. By creating an environment with controlled temperature and pressure, researchers can explore a wider range of materials and study their properties effectively.

Supersaturated State Formation: Our reactor induces convection and creates a supersaturated state in the solution, facilitating controlled crystal growth. Researchers can tailor the crystal growth process to achieve well-defined structures with specific properties.

Robust Design and Safety Features: The Hydrothermal Synthesis Reactor boasts a robust construction, ensuring durability and longevity. It incorporates safety features such as pressure relief valves, temperature monitoring systems, and automatic shutdown mechanisms, prioritizing user safety during operation.

Applications

The Hydrothermal Synthesis Reactor finds extensive applications across various fields, thanks to its exceptional capabilities in material dissolution and crystal growth:

Nanomaterials Synthesis: Researchers in fields such as electronics, photonics, and biomedical engineering benefit from the reactor’s ability to synthesize nanoparticles, nanowires, and other nanomaterials. These materials exhibit unique properties and find applications in advanced technologies.

Pharmaceutical Compounds and Drug Delivery Systems: The Hydrothermal Synthesis Reactor facilitates the synthesis of pharmaceutical compounds and the development of drug delivery systems. Controlled dissolution and crystal growth processes enable the production of nanoparticles with tailored characteristics, enhancing drug delivery efficiency and effectiveness.

Energy Storage Materials: In the field of energy storage, our reactor plays a crucial role in synthesizing advanced materials for lithium-ion batteries, supercapacitors, and hydrogen storage. These materials contribute to the development of efficient and sustainable energy storage solutions.

Crystal Growth: Crystal growth is a fundamental process in materials science, and our reactor offers an excellent platform for conducting small-scale crystal growth synthesis reactions. It enables researchers to explore crystal structures, study their properties, and advance their understanding of crystal growth mechanisms.

Material Research and Development: The Hydrothermal Synthesis Reactor serves as a versatile tool for material research and development across various disciplines. Its controlled dissolution and crystal growth capabilities provide researchers with a powerful platform to investigate and create materials with tailored properties.

Our Hydrothermal Synthesis Reactor represents a cutting-edge solution for achieving precise material dissolution and controlled crystal growth under specific temperature and pressure conditions. With its advanced features, exceptional performance, and versatility, this reactor empowers researchers and scientists to explore new frontiers in materials science, nanotechnology, pharmaceuticals, and energy storage. By investing in our Hydrothermal Synthesis Reactor, researchers gain access to a powerful tool that accelerates material dissolution, enables controlled crystal growth, and facilitates the synthesis of nanomaterial compounds. With its robust design, safety features, and precise temperature and pressure control, our reactor ensures reliable and reproducible results. Choose our Hydrothermal Synthesis Reactor to unlock the full potential of your research and innovation endeavors.

Go back to homepage

View more about Hydrothermal Synthesis Reactor on Wikipedia