Description

What Is A High Temperature Oil Bath/Water Bath?

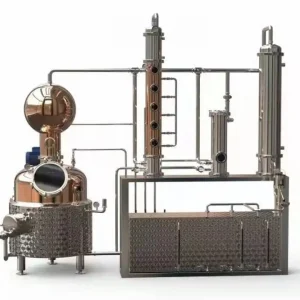

Labonsale High-temperature oil bath stands as a crucial liquid circulating equipment featuring electric heating, designed to enhance temperature control accuracy and water temperature stability. Its versatile application extends to drying, concentration, distillation, chemical reagent immersion, pharmaceutical and biological product treatments, as well as constant temperature heating for water baths and various temperature tests. Widely employed in biological, genetic, viral, environmental, medicinal, biochemical, and educational laboratories, this equipment plays an essential role in scientific research and analysis.

Functionally, high-temperature oil baths utilize a heating vessel filled with high-temperature oil or heat transfer fluid, ensuring precise and uniform thermal treatment. Samples or apparatuses are immersed in the oil, facilitating efficient heat transfer. Furthermore, these baths seamlessly integrate with other laboratory equipment such as jacketed glass reactors and rotary evaporators, where oil serves as a heat source for high-temperature reactions or inter-layer heating, complementing water’s role as a medium for heat provision in rotary evaporator applications. This synergy underscores the indispensability of high-temperature oil baths in facilitating precise heating processes across diverse scientific and industrial settings, where reliability and accuracy are paramount considerations.

Specifications Of High Temperature Oil Bath

| Model | GSC-5L | GSC -10L | GSC -20L | GSC -30L | GSC -50L | GSC-100L | GSC-150L | GSC-200L |

| Heating Power | 1.5KW | 2KW | 3KW | 4.5KW | 5KW | 6KW/9KW | 6KW/9KW | 9KW/18KW |

| Pump Power | 100W | 280W | 370W | |||||

| Flow Rate | 20L/min | 30L/min | 42L/min | |||||

| Lift Head | 4-6m | 12m | 28m | |||||

| Temp. Range | Water bath:RT ~ 99℃, Oil bath: RT ~ 200℃ | |||||||

| Temp. Control | PID control, LED Digital Display (Control Accuracy,±1℃) | |||||||

| Power Supply | 220V/50HZ,1-phase | 220V, 1-phase 380V, 3-Phase | 380V, 3-Phase | |||||

| Environmental Condition | Ambient pressure: 86kPa~106kPa, Ambient temperature:0-50℃, Ambient humidity:45%~85%RH. | |||||||

| External Circulatin Medium | Water / Heat transfer oil (Viscosity of heat transfer oil less than 500C•S•t) | |||||||

| Size of Inlet/outlet | DN15(4’’, G1/2) | DN20(6’’, G3/4) | DN25(1inch, G1) | |||||

| Connect Hose | Fluorine tube or stainless steel corrugated tube | |||||||

| Machine Size | 48*38*63cm | 55*45*78cm | 68*55*84cm | 65*80*94cm | 103*88*122cm | 90*110*130cm |

Structure

The Labonsale Heating Bath Circulator is equipped with essential features to ensure optimal functionality and user convenience. Its design includes an open-type bath lid for easy access and monitoring of samples. Real-time temperature display and a digital temperature display enable accurate tracking of temperature variations during experiments. Additionally, warning plates and parameter labels enhance safety and facilitate proper operation by providing essential information. The setting panel and heating button allow for precise temperature adjustments, while the cycle button enables efficient heating cycles. The bath’s plastic spraying shell provides durability and protection, while the heat sink ensures effective heat dissipation. Furthermore, the circulation outlet promotes uniform temperature distribution, and universal wheels enhance mobility for versatile usage in laboratory settings. Overall, the Labonsale WATEROIL BATH integrates these features to deliver reliable performance and facilitate scientific experimentation with efficiency and precision.

Details

Features

- Dual-use capability for both water and oil applications

- High precision temperature control ensured by LED screen display and PID intelligent control

- Internal and external circulation functionality

- Stainless steel circulating system provides corrosion resistance, rust prevention, and safeguards against high-temperature liquid pollution

- Controlled temperature and flow for maintaining a constant temperature environment

- The circulating pump is a stainless steel high-temperature magnetic pump with stable performance, reliable quality, and no leakage

- Optional explosion-proof design for enhanced safety

- Easy operation with lockable casters for mobility

- Energy-saving

- Simple and convenient connection facilitated by valves and pipes

- Easy-to-clean 304 stainless steel liner for hassle-free maintenance

Working Principle

The oil bath system heats oil in a container via a heating tube. A temperature sensor converts the oil temperature into an electrical signal, reflecting it as a variable quantity. This signal is compared to a predetermined setpoint. Any disparity triggers an operational amplifier to amplify the difference, which in turn activates or deactivates an actuator (such as a relay or thyristor) connected to the heating tube. This feedback loop ensures the temperature stabilizes at the desired setpoint for precise control during experiments.

What Is The Best Oil For Hot Oil Circulator?

In research laboratory settings, mineral oil or silicone oil is commonly employed as the medium for oil baths, particularly for reactions necessitating heating or reflux temperatures of up to 200 °C. Oil baths are favored due to their capacity to deliver a more uniform distribution of heat compared to alternative heating devices.

Maintenance Tips For High Temperature Oil Bath

To prolong the lifespan and efficiency of high temperature oil baths, follow these maintenance tips:

- Regularly inspect and clean the bath and heating elements.

- Replace the oil periodically to prevent degradation and contamination.

- Calibrate the temperature control system as needed to maintain accuracy.

- Store the bath in a clean and dry environment when not in use.

Operating Manuals

- Place the oil bath chemistry lab on a level workbench and ensure its appearance is undamaged. Check the instrument’s overall condition, inspect the power cord for any damage, verify the flexibility of the power switch, ensure the tertiary plug is intact, and use a power socket with safety grounding.

- To extend the instrument’s service life, avoid moisture in the control box to prevent leaks.

- For safety purposes, always connect the ground wire when using the equipment.

- After concluding the experiment, begin by deactivating the cycle switch, followed by adjusting the heating knob to the low/zero setting. Proceed to switch off the heating switch, and finally, turn off the power switch to cut off the power supply.

- Before powering on, ensure the equipment is refueled; dry burning is strictly prohibited.

- In case of potential hazards, refer to targeted emergency procedures such as immediate power shutdown or using fire blankets to smother flames.

Go back to homepage

View more about Oil Bath on Wikipedia