Description

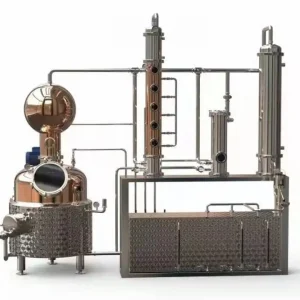

The distillation column, also known as a fractionating column or rectification column, serves as a critical gas-liquid contact device in separating and purifying liquid mixtures, particularly within the chemical and petrochemical industries. Operating on the principle of fractional distillation, this specialized column capitalizes on the varying volatility of components in a mixture.

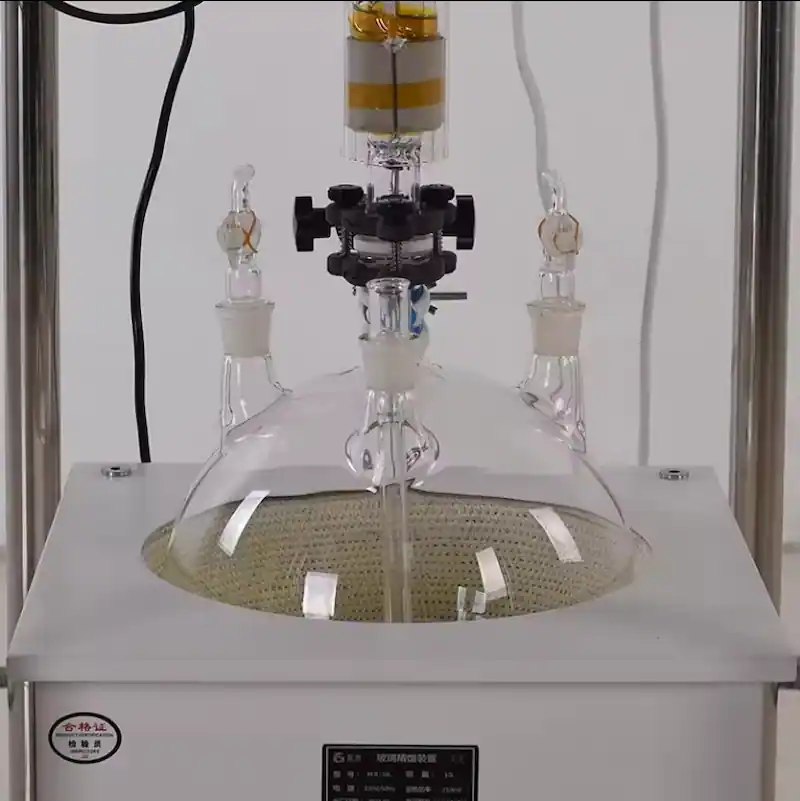

Characterized by high separation efficiency and operational simplicity, the Labonsale distillation column is a fundamental tool in these applications. Its structural composition typically includes a tower kettle, heating bath or electric heating jacket, distillation column, splitter head, vacuum separator sampling collection bottle, controller, distillation column packing, and frame.

Initiating the distillation process involves heating the liquid mixture to its boiling point. As vaporization occurs, the mixture ascends through the column, equipped with trays or packing materials. Segmented into sections, each maintained at distinct temperatures, the column allows for the condensation and separation of components with lower boiling points from the ascending vapor.

On the trays or packing material, mass transfer between the liquid and vapor phases enhances the separation process. The resulting condensed liquid termed the distillate or overhead product, accumulates at the column’s top. Concurrently, the remaining liquid, referred to as the bottoms or residue, is collected at the bottom.

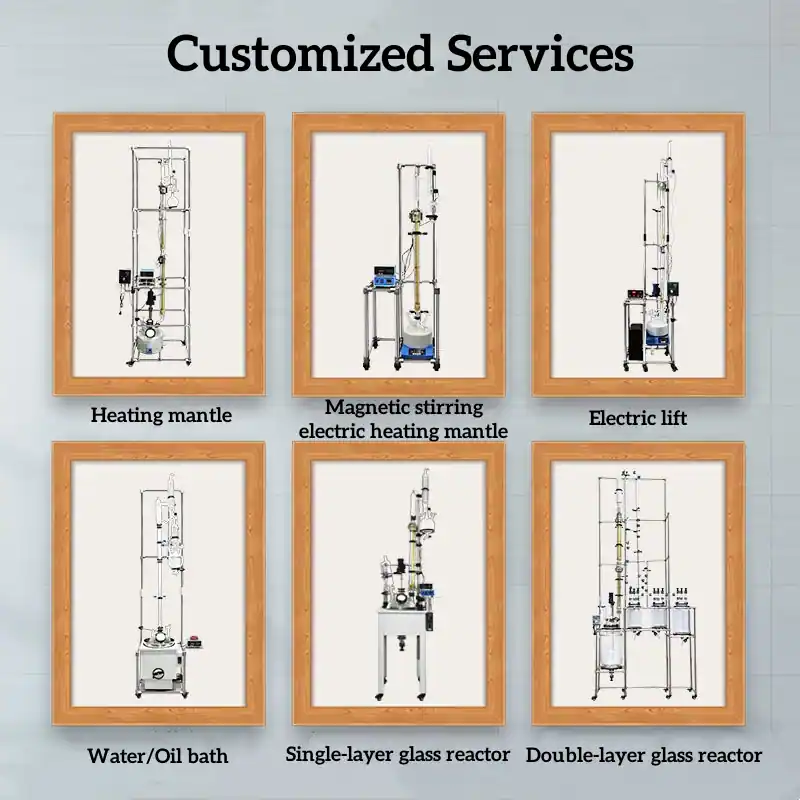

Glass Distillation Column Customized Services

- Heating mantle

- Magnetic stirring electric and heating mantle

- Electric lift

- Water/Oil bath

- Single-layer glass reactor

- Double-layer glass reactor

Distillation column Technical Parameter

| Model | Column Internal Diameter(mm) | Column Internal Height(mm) | Port | Heating Power |

| 523416500 | 16 | 500 | 24# | 100W |

| 523416700 | 700 | |||

| 5234161000 | 1000 | |||

| 5234161300 | 1300 | |||

| 5234161500 | 1500 | |||

| 523420500 | 20 | 500 | 24# | 200W |

| 523420700 | 700 | |||

| 5234201000 | 1000 | |||

| 5234201300 | 1300 | |||

| 5234201500 | 1500 | |||

| 523425500 | 25 | 500 | 29# | 300W |

| 523425700 | 700 | |||

| 5234251000 | 1000 | |||

| 5234251300 | 1300 | |||

| 5234251500 | 1500 | |||

| 523430500 | 30 | 500 | 29# | 500W |

| 523430700 | 700 | |||

| 5234301000 | 1000 | |||

| 5234301300 | 1300 | |||

| 5234301500 | 1500 |

Details

The efficiency of a Labonsale distillation column hinges on various factors such as column design, temperature control, and the selection of appropriate packing or trays. Often labeled as a rectification column, this type of distillation column finds widespread application in industries where the precise separation and purification of chemical compounds are paramount, including fuel, chemical, and pharmaceutical production.

In the context of distillation, interchangeable terms such as fractionating column, rectification column, and column still are used. The design and operation of a Labonsale distillation column play a pivotal role in optimizing the separation of different components within a liquid mixture, ensuring efficiency and reliability in the production process.

During the fractionation process, thorough gas-liquid contact and multiple heat exchanges occur. This results in the separation of most low-boiling-point components at the column’s top from the distillation head, while high-boiling-point components remain in the collection bottle. This iterative fractionation achieves the separation of multiple components with distinct boiling points, serving the purpose of fractional distillation and substance purification.

The technique is well-suited for the separation and purification of various organic mixtures in fields such as medical research, petrochemistry, and the food industry. Examples include the distillation of petroleum distillate alcohol ethers and volatile oils in traditional Chinese medicine, conducted under normal or reduced pressure conditions.

Go back to homepage

View more about Fractionating column on Wikipedia