Description

SHZ-DIII Desktop Circulating Water Vacuum Pump, also known as recirculating water vacuum pump, water recirculating aspirator pump, Water Circulating Vacuum Pump, Water Jet Vacuum Pump, water ring vacuum pump, etc. It uses water as the working fluid to create a vacuum by removing air or other gases from a sealed chamber. This versatile pump is commonly used in laboratories and industrial settings for a variety of processes, including evaporation, distillation, crystallization, drying, sublimation, and vacuum filtration.

Types of SHZ-DIII Desktop Circulating Water Vacuum Pump

The SHZ-DIII Desktop Circulating Water Vacuum Pump is available in four main types: PTFE, Anti-corrosion, Stainless Steel, and Four Vacuum Port.

Technical Parameters of SHZ – DIII Desktop Circulating Water Vacuum Pump

| SHZ-DIII Model | PTFE type | Anti-corrosion type | Stainless steel type | Four vacuum port type | |

| Motor performance | Power | 180W | 370W | ||

| Pumpage | 80L/Min | 370W | 80L/Min | 80L/Min | |

| Lift | 10m | ||||

| Body material | Anti-corrosion | 18L | |||

| Voltage | 220V/50HZ | ||||

| Function 1 | Maximum vacuum | 0.098Mpa (98KPa,735mmHg, 0.98bar, 735Torr) | |||

| Single port sucking volume | 10L/Min | 80L/Min | |||

| Vacuum port no. | 2Pcs | 2Pcs | 2Pcs | 4Pcs | |

| Tank capacity | 15L | 18L | |||

| Shell material | PP | ||||

| Function 2 | As circulating pump | Circulating water temperature: 0~25℃ | |||

| Dimensions | 400*280*420mm | ||||

| Packing size | 480*380*560mm | ||||

| Net weight | 15KG | ||||

| Noise | <50dB | 2Pcs | 2Pcs | 2Pcs | |

| Features | Anti-corrosion pump head, full PTFE vacuum bottle | Pump head engineering plastic, anti-corrosion vacuum bottle | All stainless steel pump head, anti-corrosion vacuum bottle | Four suction ports and vacuum gauges, anti-corrosion vacuum bottle and pump head |

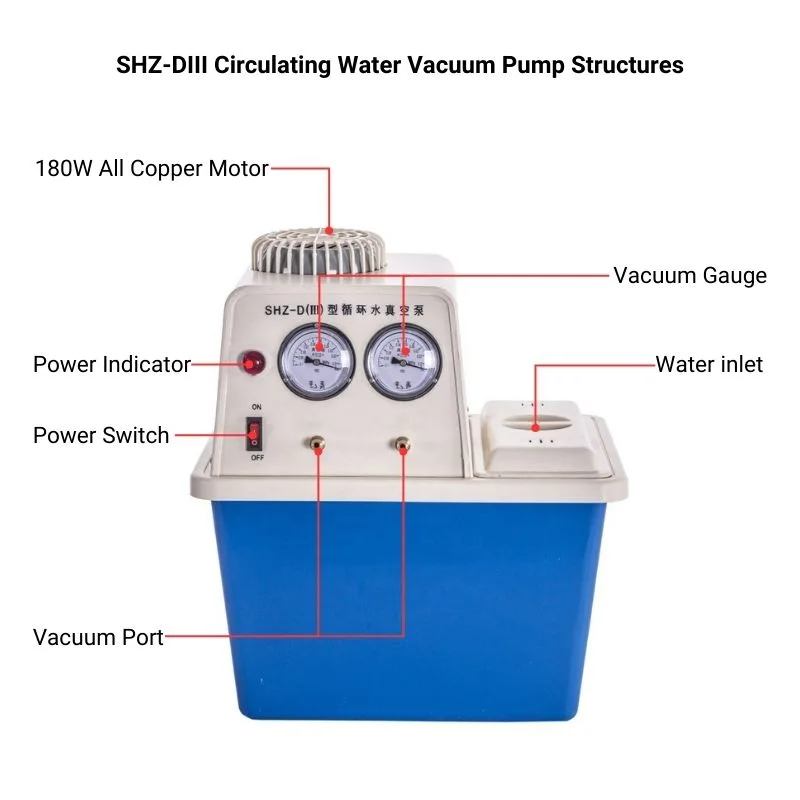

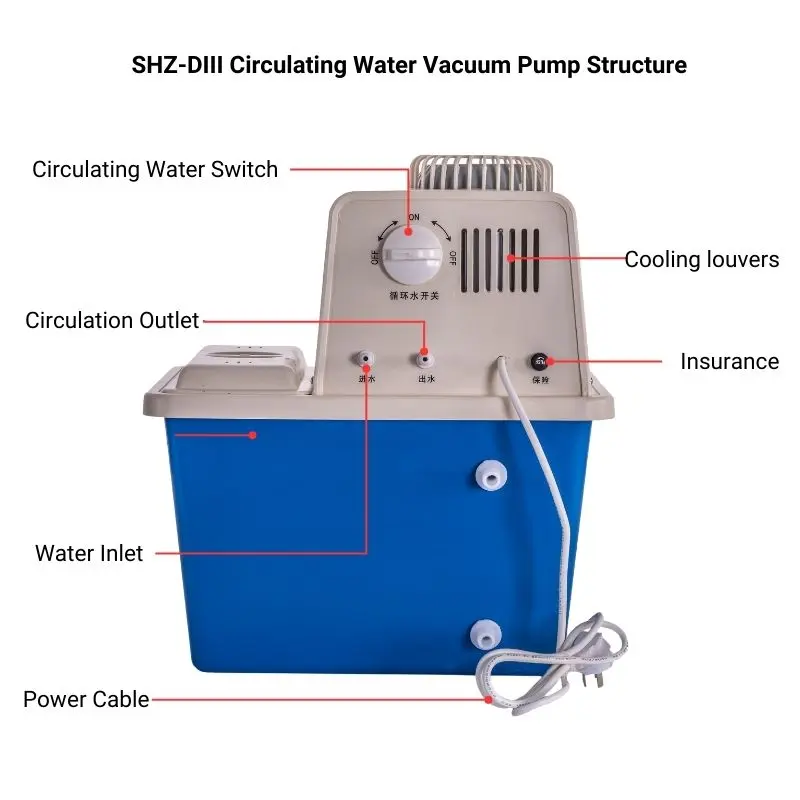

Structures

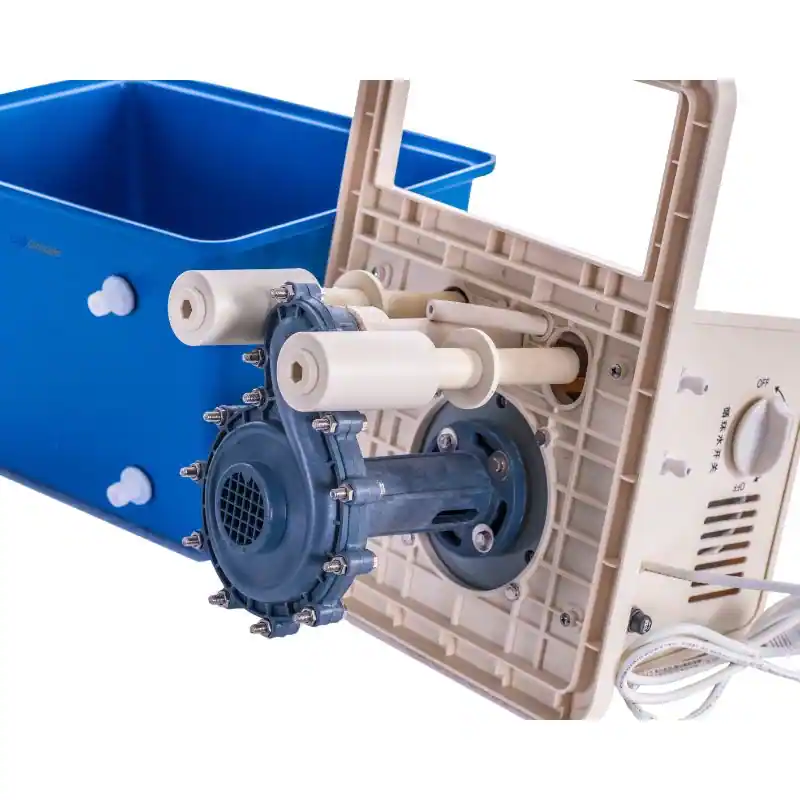

Details

Equipped with durable copper and PTFE check valves to prevent vacuum backflow, this unique and innovative cutting-edge technology ensures reliable performance.

The turbocharged turbine with a six-channel, double-sealed impeller efficiently passes large amounts of water.

The high-strength ABS plastic shell, molded in one go, is compact, lightweight, and beautifully designed.

Recommended Turnkey Solutions

We recommend connecting the SHZ-DIII Desktop Circulating Water Vacuum Pump to support various applications, including rotary evaporators, glass reactors, short path distillation units, and other related equipment.

Functions

SHZ-DIII Desktop Circulating Water Vacuum Pump uses water and jet technology to create negative pressure. It serves as both a vacuum suction device and a cooling water provider for reactors, making it essential for scientific research and industrial processes.

Applications

- Evaporation

- Distillation

- Crystallization

- Decompression sublimation

- Vacuum filtration

- Vacuum degassing

- etc.

Ideal For:

- Universities and Research Institutes

- Chemical and Pharmaceutical Industries

- Biochemistry and Medical Services

- Food and Agricultural Engineering

- Biological Engineering

Uses Cases

- Industrial Manufacturing: Coating, heat treatment, vacuum sealing.

- Laboratory Research: Creating vacuum environments for material testing.

- Chemical Engineering: Controlling gas pressures in reactions.

Medical Equipment: Assisting in surgical and therapeutic procedures.

Features

The SHZ-DIII Desktop Circulating Water Vacuum Pump is a versatile, efficient, and durable solution for various laboratory and industrial applications. Its advanced features, including oil-free operation, corrosion resistance, significant water and energy savings, and low noise, make it an excellent choice for processes like rotary evaporation, vacuum filtration, and more. The compact, user-friendly design, coupled with its ability to handle corrosive gases and provide stable vacuum conditions, ensures reliable performance in diverse environments.

Key Characteristics:

- Oil-Free and Corrosion-Resistant: The recirculating water vacuum pump is designed for reliability in chemical-related operations, using PTFE for major valves and parts, eliminating the need for oil changes and cold traps for water/alcohol solutions.

- Easy Maintenance: Specifically designed for laboratory environments, the Water Jet Vacuum Pump is straightforward to maintain.

- High Compatibility: Ideal for use with rotary evaporators, vacuum filtration, and other laboratory processes.

Advanced Design:

- Anti-Corrosion Shell: The high-quality, anti-corrosion shell protects the pump from chemical damage.

- Flexible Operation: Newly developed 5 taps can work independently or together with a 5-way pipe (optional) to increase extraction capacity, suitable for large rotary evaporators and reactors.

- Materials: Features a copper jet and PP triple-valve, check valve, and suction mouth.

Enhanced Performance:

- Gas Ballast Valve: Effectively removes water vapor, preventing oil and water vapor mixing, thereby extending the pump’s service life.

- Negative Pressure Generation: Utilizes jet technology to achieve an ultimate vacuum of 3000-6000Pa.

- Compact and Attractive: Designed for space-constrained laboratories, it is small, lightweight, and visually appealing.

- Dual Tap Air Extraction: Equipped with multiple taps for versatile air extraction options.

Water and Energy Efficiency:

- Significant Water Savings: Water can be reused repeatedly, making it suitable for high-floor laboratories with limited water supply or low pressure.

- Energy Efficiency: Saves over 35% more electricity compared to other vacuum pumps.

Noise Reduction and Stability:

- Fluid Muffler: Reduces gas in water, enhancing vacuum stability and minimizing noise by reducing gas-liquid friction.

- Low Noise: Operates quietly and includes a check valve on the exhaust pipe to prevent backflow of water into the vacuum equipment.

Corrosion Resistance and Non-Pollution:

- Durable Materials: The pump spindle is made from stainless steel, and key components are constructed from acid and alkali-resistant materials.

- Non-Polluting: The entire plastic water tank resists corrosion from acids, alkali solutions, and other chemicals, ensuring no oil pollution in the laboratory.

User-Friendly Design:

- Easy to Operate: The pump head is submerged directly in water, eliminating complex water diversion devices. The upper part has a movable cover for easy water, ice, and maintenance access.

- Mobility: Equipped with steering wheels for easy movement around the laboratory.

Specialized Features:

- Multiple Pumping Holes: Can be used alone or with two vacuum gauges.

- Material Durability: The body is made from stainless steel and special plastics, with the tank constructed from corrosion-resistant plastic.

- Vacuum Stability: The custom fluid muffler ensures higher and more stable vacuum pressure.

Operation Manual

1) Add Enough Circulating Water.

Put the machine smoothly on the working place. When first use, open the lid and fill the tank with cooling water. Once added water can be reused, but to change the water at least once a week.

2)Connect Tube

Find the “Y” three-way pipe in the package, corresponds to two vacuum ports to install it with the match equipment.

3)Power On To Made Vacuum Operation

Before power on, need checking the circulating switch is closed, then press the power switch on the vacuum pump can working for vacuum, the vacuum degree can view the vacuum meter.

4)As Circulating Pump

Connect the vacuum device to the inlet and outlet corresponding, rotating the circulating witch to “ON”, can operate continually circulating water to reactor.

5) Improve Vacuum

When the machine needs long time operation, in order to guarantee water temperature in the water tank not rising, the vacuum degree not reduce, and not affect the experimental operation, you can connect the water hose with water source (or tap water), forming a natural outside circulation status, and it can remain the water temperature inside not rise, and the vacuum not reduce.

Maintenance Tips

- Regular Water Replacement: Replace the water in the flume regularly to maintain water quality, vacuum degree, and avoid dirt stains.

- Handling Corrosive Gases: When extracting corrosive gases, shorten the water replacement period.

Common faults and maintenance methods

| Fault | Fault Cause | Maintenance Methods |

| No vacuum | 1. Vacuum taps blocked by sundries.

2. The filter at the bottom blocked by sundries. 3. Vacuum taps coil buckling loose |

1.Eliminates the nozzle sundries.

2.Eliminates the filter sundries, keep the water clean. 3.Tighten the coil by hand. |

| Vacuum meters hands do not move or swing | 1.Ventilation keyway of sealing screws behind the meters blocked.

2.Meter hands swing, because of the backwater valve or the vacuum nozzle leaks air. |

1.Remove the vacuum meters,clean the ventilation keyway.

2.Tighten the rubber hose connection plug, check the backwater valve pad, clean the backwater valves, tighten the vacuum nozzle. |

| Do not start or leakage | 1. After power, the motor humming but not start is for the fan blade is out of work.

2. The motor suddenly stopped was because line outage or the fuse explodes. 3. The cover hemp hand, mainly because of the wire connect the shell or the plug without earth wire. |

1.Cut off the power, use water prod the blades inside the motor cover to help move a few laps and then turn it on again.

2.Check the circuit, Replace the fuse and dredge the circuit. 3.Exclude shell connect, add the earth wire. |

| Matters need attention | Because the pump with mechanical seal, start only after adding water, but empty running is strictly prohibited, in case the mechanical seal part damaged. | |

Go back to homepage

View more about Vacuum pump on Wikipedia