Description

The vacuum drying oven finds extensive application in various fields including biochemical, chemical engineering, pharmaceuticals, medical care, public health, agricultural scientific research, and environmental protection. It is particularly suitable for the rapid and efficient drying of heat-sensitive, easily decomposed, easily oxidized materials and complex components. Additionally, it is highly effective for disinfection, sterilization, and drying of various glass containers.

Specifically designed to cater to heat-sensitive, easily decomposed, and easily oxidized substances, our vacuum drying oven utilizes high-temperature drying under vacuum conditions. This significantly reduces the boiling point and vapor pressure, creating a dust-free and non-turbulent heating process. The gentle drying environment facilitates easy collection, discharge, and reuse of solvent vapors. Furthermore, the oxygen-free or inert gas environment ensures that storage, heating, testing, and drying take place without oxidation, preserving the integrity of test samples.

We offer a selection of vacuum drying ovens ranging from 20 to 500 liters in capacity, constructed from materials such as iron plate, 201 stainless steel, and 304 stainless steel. Our product line includes a variety of customizable options to meet your precise requirements. These options encompass diverse chamber sizes, temperature parameters, control systems, and supplementary features, all designed to align with your specific demands.

| Volume | 25L, 50L, 90L, 215L, 500L, Customized |

| Material | Iron plate, 201 Stainless steel, 304 stainless steel |

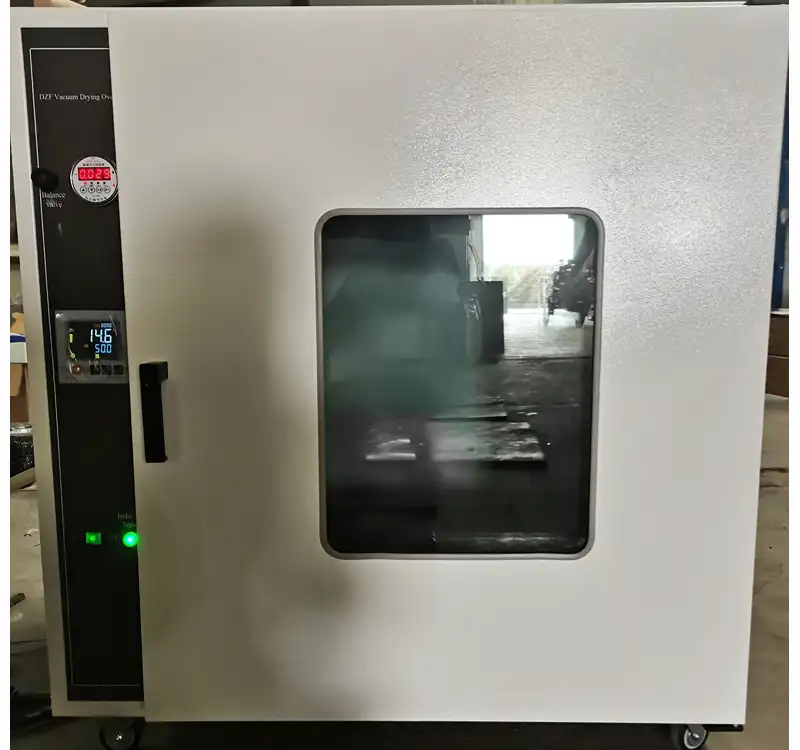

Product Real Shot

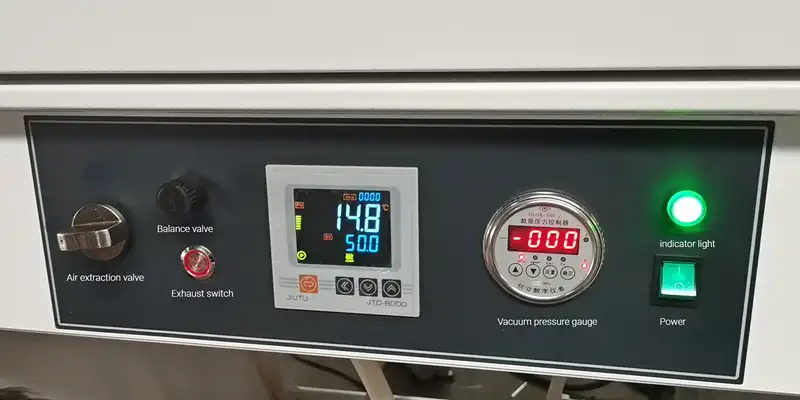

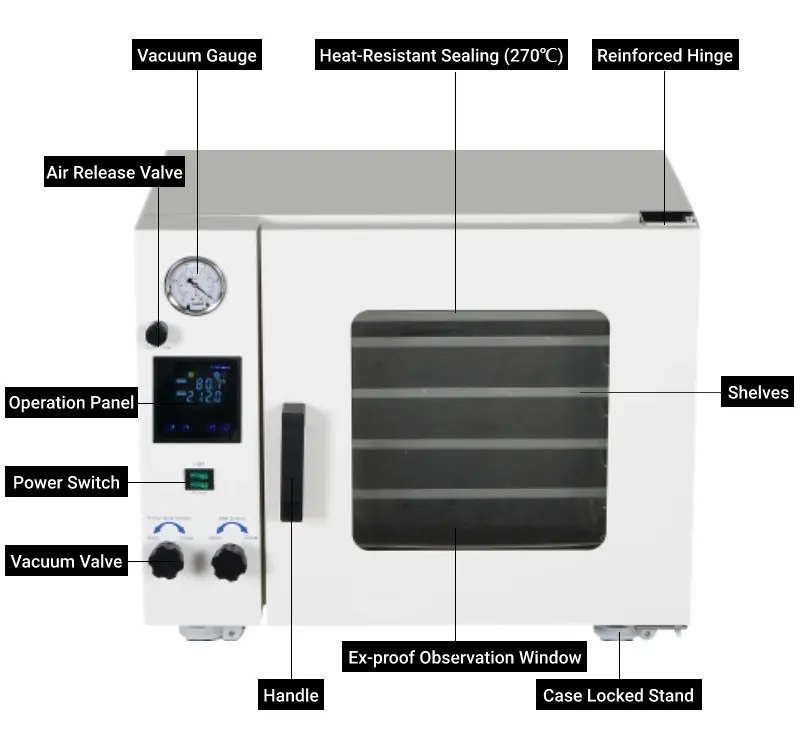

Product Component of Vacuum Drying Oven

Our vacuum drying oven is a state-of-the-art drying solution designed to meet the demanding needs of industries requiring efficient and precise drying processes. With advanced technology and meticulous craftsmanship, this oven offers superior performance, exceptional product quality, and unmatched reliability.

Key Features and Technologies

Precise Temperature Control:

Our vacuum drying ovens utilize state-of-the-art temperature control systems, allowing users to set and maintain accurate drying temperatures with minimal fluctuations. This ensures consistent and reliable drying results, even for heat-sensitive materials.

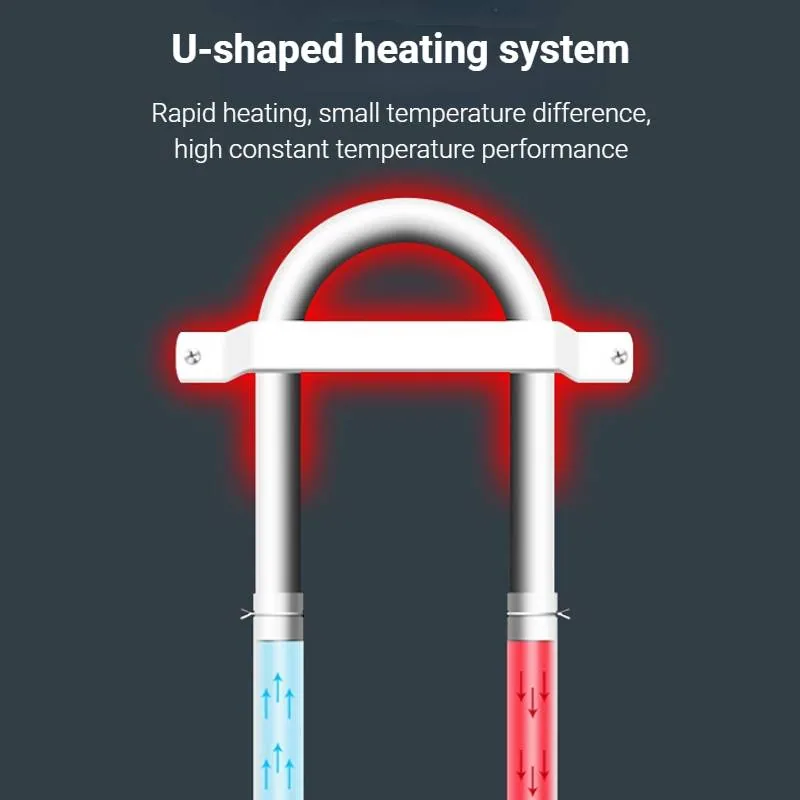

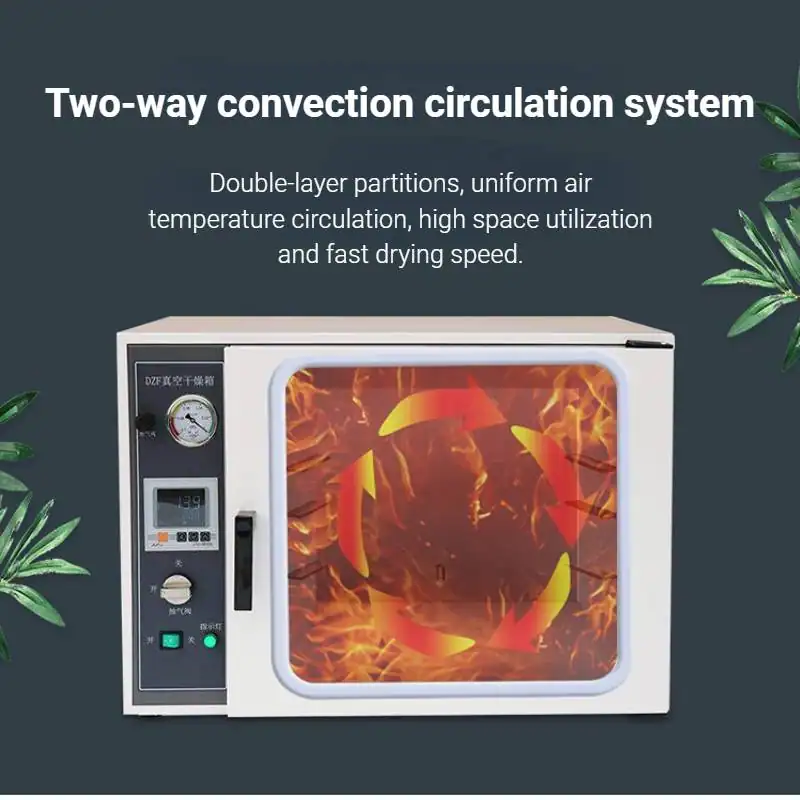

Uniform Heating:

To achieve uniform heat distribution, our vacuum drying ovens employ advanced heating elements and air circulation systems. This design feature guarantees homogeneous drying throughout the chamber, eliminating the risk of hotspots and ensuring uniform product quality.

Vacuum System:

The integral vacuum system in our ovens enables precise control over the drying environment. By lowering the pressure, volatile compounds can evaporate at lower temperatures, preserving the integrity and properties of the materials being dried.

Safety Features:

We prioritize the safety of our users and their operations. Our vacuum drying ovens are equipped with multiple safety features, such as automatic pressure release valves, over-temperature protection, and door interlocks, ensuring safe and secure drying processes.

Benefits of Vacuum Drying Ovens:

Enhanced Product Quality:

The low-temperature and reduced-pressure conditions in our vacuum drying ovens minimize thermal stress and prevent oxidation, resulting in higher product quality. This is especially critical for delicate or sensitive materials, pharmaceutical products, electronic components, and heat-sensitive substances.

Faster Drying Times:

Due to the reduced boiling point of water under vacuum conditions, our ovens can significantly shorten drying times compared to traditional drying methods. This increased efficiency translates into improved productivity and reduced energy consumption.

Versatile Applications:

Our vacuum drying ovens find applications across various industries. They are ideal for drying heat-sensitive materials, such as polymers, pharmaceuticals, electronic components, and food products. Additionally, they are utilized in research laboratories, manufacturing facilities, and quality control departments.

Cost and Energy Efficiency:

By employing advanced drying technologies, our vacuum drying ovens offer excellent cost and energy efficiency. The reduced drying times and lower operating temperatures contribute to energy savings, while the enhanced product quality reduces the need for rework or waste, leading to cost optimization.

Customization Options:

We understand that each industry and application has unique requirements. Therefore, we offer a range of customization options for our vacuum drying ovens. These include different chamber sizes, temperature ranges, control systems, and additional features tailored to your specific needs.

Warranty and After-Sales Service:

We are committed to providing top-notch customer service and support. All our vacuum drying ovens come with a comprehensive warranty, ensuring peace of mind. Additionally, our experienced technical team is readily available to assist with installation, training, maintenance, and troubleshooting, ensuring smooth and uninterrupted operations.

Go back to homepage

View more about Vacuum Drying on Wikipedia