GLASS REACTOR

- Single-layer / Dual-layer / Triple-layer available

- Manual lift / Electric lift Optional

- 1~200 liter for choice

- Customized services

- Warehouse in USA | Canada | Spain | Thailand with fast delivery.

- One-stop turnkey solution

- Competitive Prices

- Certified Products

- Best After-sale Service

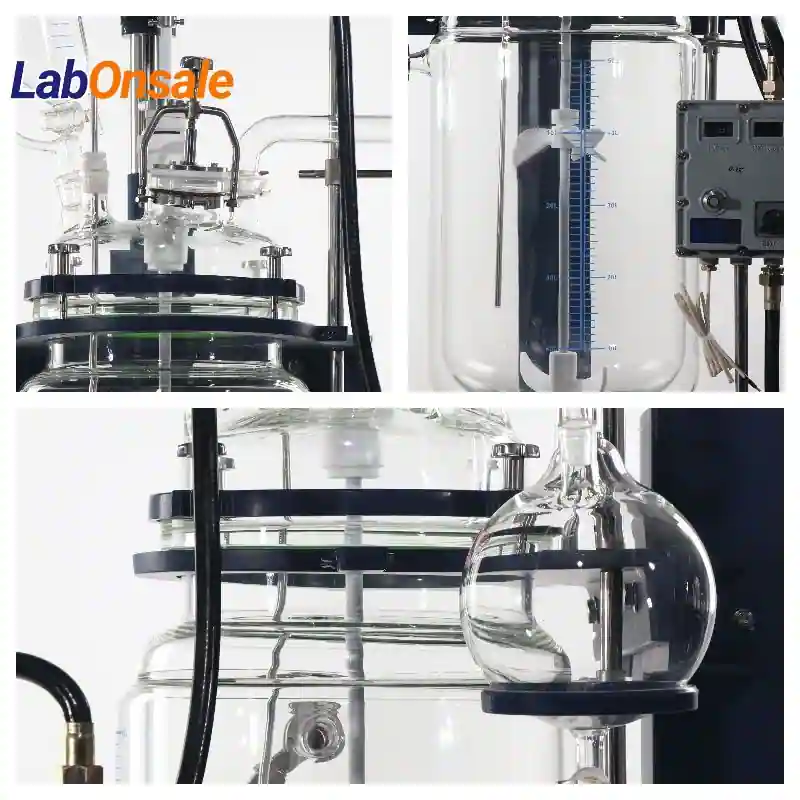

Labonsale glass reactors and process equipment ensure optimal performance across laboratories, pilot plants, and production environments. Our systems are designed for seamless scale-up from lab synthesis to full-scale production. Built with high-quality borosilicate glass and corrosion-resistant materials like glass-lined steel, fluoropolymers, and Hastelloy®, Labonsale is your trusted partner for reliable and durable solutions.

Single Layer Glass Reactor

Structure

- Desktop

- Hemispherical bottle with frame

- Cylindrical bottle with frame

Volume

1~100 Liter Available

Two Heating Method

- Water & Oil Bath(Up to 250℃)

- Heating Mantle(Up to 350℃)

Single-layer glass reactor uses a water/oil bath or heating mantle to directly heat the vessel, allowing materials to react at a constant temperature with stirring. It enables reactions under atmospheric or negative pressure, with reflux, distillation, and extraction capabilities in a sealed environment.

Technical Parameter

| Model | F-1L | F-2L | F-3L | F-5L | F-10L | F-20L | F-30L | F-50L | F-80L | F-100L |

|---|---|---|---|---|---|---|---|---|---|---|

| Capacity(L) | 1 | 2 | 3 | 5 | 10 | 20 | 30 | 50 | 80 | 100 |

| Heating Power(kW) | 0.8 | 1.5 | 1.8 | 2 | 3 | 4.5 | 6 | 9 | 9 | |

| Constant Pressure Drop Funnel | 250ml | 1000ml | 2000ml | |||||||

| Temperature Range(℃) | RT-250 (Heating in water & oil bath) RT-350 (Heating with heating mantle) | |||||||||

| Voltage | 220V/50Hz or 380V/50Hz (110V/60Hz Optional) | |||||||||

| Optional | ·Ex-proof Motor,Ex-proof Controller | |||||||||

| ·Plug Type | ||||||||||

| ·PTFE spraying anti-corrosion treatment |

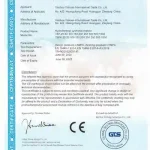

Dual Layer(Jacketed) Glass Reactor

Volume

1~200 Liter Available

Anti-corrosion Material

- High borosilicate glass

- PTFE discharge valve

- All parts contact material use PTFE

Temperature Range

-80~+250℃

Voltage

220V/50Hz or 380V/50Hz (110V/60Hz Optional)

The jacketed glass reactor features double-layer glass. The inner layer holds the reaction solvent for stirring, mixing, and filtering, while the outer layer connects to heating or cooling sources for temperature control during the reaction.

Technical Parameter

| Model | S-1L | S-2L | S-3L | S-5L | S-10L | S-20L |

|---|---|---|---|---|---|---|

| Reaction Capacity | 100ml~1L | 200ml~2L | 500ml~ 3L | 500ml~ 5L | 2L~ 10L | 2L~ 20L |

| Jacketed Volume(L) | 1 | 1.5 | 1.5 | 2 | 3 | 6 |

| Port no. on the lid | 4+1 | 4+1 | 4+1 | 4+1 | 5+1 | 5+1 |

| Temperature Range | -120~+300 ℃ | |||||

| Constant Pressure Drop Funnel | 250ml | 1000ml | ||||

| Stirring Speed(rpm/min) | 0-1200 | 0-600 | ||||

| Voltage | 220V/50Hz or 380V/50Hz (110V/60Hz Optional) | |||||

| Dimension(mm) | 440*360 *1325 | 520*500 *1510 | 670*690 *1920 | 720*700 *2020 | ||

| Optional | ·Receiving Flask | |||||

| ·Filter Device | ||||||

| ·Rectification System | ||||||

| ·Ex-proof Motor,Ex-proof Controller | ||||||

| ·Plug Type | ||||||

| ·PTFE spraying anti-corrosion treatment |

| Model | S-30L | S-50L | S-80L | S-100L | S-150L | S-200L |

|---|---|---|---|---|---|---|

| Reaction Capacity | 5L~ 30L | 5L~ 50L | 10L~ 80L | 10L~ 100L | 25L~ 150L | 30L~ 200L |

| Jacketed Volume(L) | 10 | 16 | 24 | 30 | 35 | 40 |

| Port no. on the lid | 5+1 | 5+1 | 5+1 | 5+1 | 5+1 | 5+1 |

| Temperature Range | -120~+300 ℃ | |||||

| Constant Pressure Drop Funnel | 1000ml | 2000ml | 5L | |||

| Stirring Speed(rpm/min) | 0-600 | |||||

| Voltage | 220V/50Hz or 380V/50Hz (110V/60Hz Optional) | |||||

| Dimension(mm) | 650*750 *2400 | 750*700 *2450 | 770*720 *2480 | 780*730 *2500 | 1240*1140 *3100 | 1300*950 *3100 |

| Optional | ·Receiving Flask | |||||

| ·Filter Device | ||||||

| ·Rectification System | ||||||

| ·Ex-proof Motor,Ex-proof Controller | ||||||

| ·Plug Type | ||||||

| ·PTFE spraying anti-corrosion treatment |

Triple Layer Glass Reactor

A triple-layer glass reactor allows heating and cooling through its jacket and can be operated under negative pressure. A constant pressure funnel or regulating valve controls the precise addition of materials, while the condenser’s heat exchange function enables the distillation and recovery of reaction products.

Recommended supporting equipment

- High and LowTerperature CirculatingDevice

- Chiller

- Vacuum Pump

- High Temperature Circulating Water/oil Bath

Electric Lift Glass Reactor

Traditional glass reactors are difficult to clean and provide sub-optimal mixing. Our electric lift glass reactor offers easy disassembly and improved material handling, making it ideal for synthesis, distillation, and concentration experiments. Widely used in the pharmaceutical, chemical, petrochemical, and new material industries, it excels in pharmaceutical synthesis and fine chemical processes.

Volume

10~50 Liter Available

Temperature Range

-80~+250℃

Voltage

220V/50Hz or 380V/50Hz (110V/60Hz Optional)

Technical Parameter

| Model | SJ-10L | SJ-20L | SJ-30L | SJ-50L |

|---|---|---|---|---|

| Capacity(L) | 10 | 20 | 30 | 50 |

| Jacketed Volume(L) | 8 | 7 | 9 | 16 |

| Stirring Speed(rpm/min) | 0~450 | |||

| Power(W) | 130 | 160 | ||

| Voltage | 220V/50Hz or 380V/50Hz (110V/60Hz Optional) | |||

| Temperature Range(℃) | -80~+250 | |||

| vacuum degree | 0.098MPa | |||

| Dimension(mm) | 700*850*2250 | 750*920*2400 | 750*950*2700 | 750*950*2950 |

| Weight(Kg) | 120 | 130 | 142 | 148 |

| Optional | ·Plug Type | |||

| ·PTFE spraying anti-corrosion treatment | ||||

| ·Ex-proof Motor,Ex-proof Controller |

Customized Cases

- Explosion-proof

- PTFE spraying anti-corrosion treatment

- Filtration and crystallization

- Customized thermal jacket

- Electric Lift

- Other customized service

We offer customized glass reactors to meet unique customer needs. For hazardous environments, we provide explosion-proof reactors, and for aggressive chemicals, PTFE-coated reactors for superior corrosion resistance. Custom assemblies for filtration and crystallization are available, along with reactors featuring thermal jackets for precise temperature control. These options ensure optimal performance and reliability tailored to your specific requirements.

One-stop Turnkey Solution

Glass reactors are typically integrated with high and low temperature circulators, chillers, vacuum pumps, and high-temperature water or oil baths for optimal operation. We offer a one-stop solution, allowing you to source all necessary equipment directly from us.

Features

- Corrosion Resistance: Made from high-quality borosilicate glass, these reactors resist chemical corrosion, enduring harsh chemicals like acids and bases without degrading.

- Transparency: The clear glass design allows easy observation of reactions, making it ideal for monitoring color changes or precipitate formation.

- High Temperature Resistance: Borosilicate glass handles extreme temperatures, from -80°C to 250°C, making it suitable for various reactions.

- Precise Temperature Control: The jacketed design ensures precise temperature regulation, with heating or cooling fluids circulating to maintain consistent conditions.

- Efficient Mixing: The stirrer provides effective mixing, improving reactant contact, speeding up reactions, and enhancing yields.

- Frequency Conversion Motor: Ensures stable operation, large torque, automatic boosting, with no sparks or noise, and long service life.

- Easy Maintenance: The smooth, non-reactive glass surface simplifies cleaning and reduces the risk of cross-contamination.

Video

Certificates

24/7 Online

Customized solutions

Competitive quotation

Fast delivery

Installation guide

Video communication

All life maintenance

After-sale return visit

Online support

Pre-sale service

Sales service

After-sales service